This post contains the DYNO graphs and DYNO video along with a discussion and theory content.

You might be wondering why I waited soooo long to dyno the car.

There are many reasons, and I think it worth a minute to stop and examine the main ones, other than I am worried that it might explode violently because what crazy runs 15psi without methanol in this kind of weather on purpose? Okay, we will get to alcohol land, I promise. But first, I need to establish some baseline rules to the highest mileage LS for my collection of data, because this is my first LS engine ever and I have no idea what I am doing, or it is

really capable of. This is the moment to make mistakes.

If search for tuning knowledge we get a VAST array of results. I was curious about stuff I had never seen before like transmission shift pressure. Just because five ways are different doesn't make them wrong. But not everything that comes with the Original computer is safe to use either.

Tuning the OEM ecu is like tuning an incredibly complex interworking of maps and numbers for which around half of, I have no idea what it does and the description is vague. There is an overwhelming abundance of maps to fiddle and fuss over, and yet somehow it manages to lack fundamentally useful features that every stand-alone does have. A lack of real time tuning where applicable & any model of having to shut down the engine to actually send a tune file is limiting in that one can not adjust in real time to see what something does or causes. So for most of the tuning I have done so far, I did the way they usually tell you not to do it, that is, by adjusting the variables by "feel" and then just uploading and assuming I was right. It has gotten me into trouble but then again Empirical testing is always necessary to some extent no matter what the application when setting up new hardware.

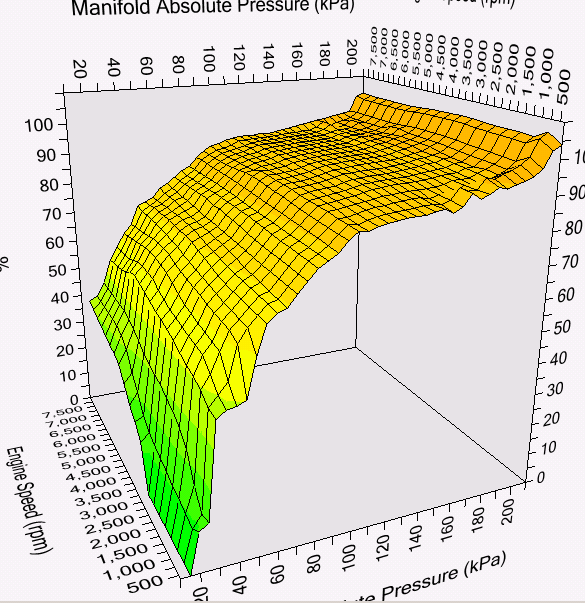

The OEM ecu once dialed in, is actually potentially easier to tune than a stand-alone over time, because it makes use of exact masses of air and fuel wherever stand-alones tend to be very general in their approach to fuel and timing. For example a stand-alone usually has a main timing map where you would expect to see applicable timing values.

In the OEM ecu, the main spark table depends on at least 10 different maps, all configured "already for you" (HAHAHAahahaha... good luck) by the OEM manufacturer, and are some hidden or disabled or difficult to discern what it's really going to do. For example if you put a negative value into the "PE Adder" map it will dump 999% fuel injector duty cycle to your engine. Not joking, it could hydrolock the engine to put the wrong value into one of those many tables. You have to know what you can do, and what NOT to do, and what you can get away with.

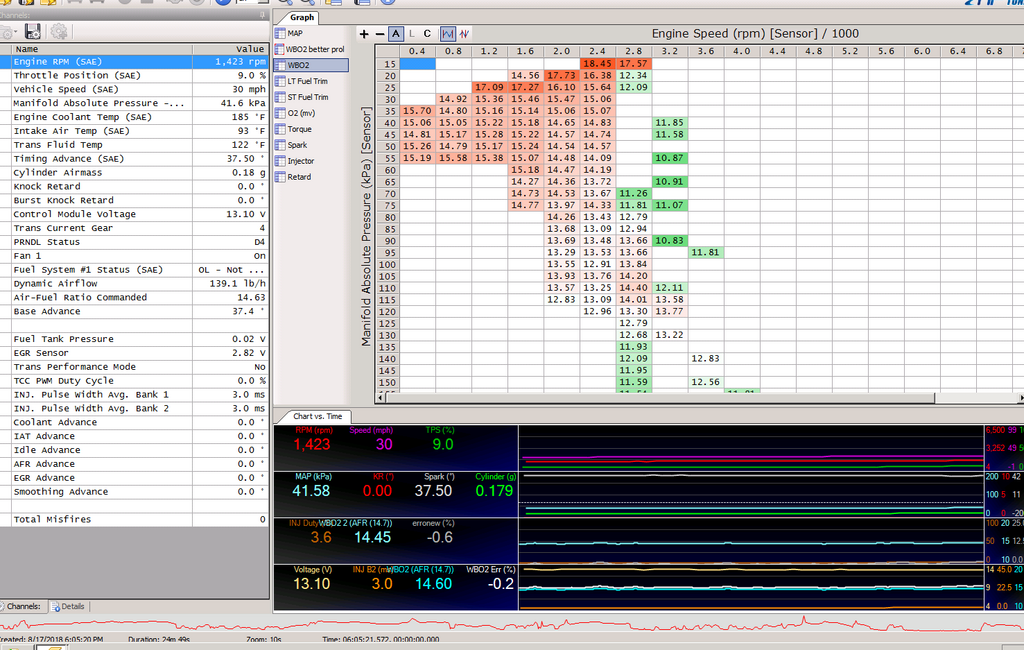

The timing map itself reads in "g/cyl" whatever the heck that means is up to you though, there are ways to 'fool' the computer but I don't recommend trying because it can influence transmission pressure among many other things I think, seems like too much work. Most boost setups are going to peg 1.2g/cyl limit in this ECU so there is alot of complaining on the forums, some talk of "scaling" but I have found a somewhat water down solution using a map called 'afr advance' which allows you to avoid scaling. The computer has no way of knowing whether you are seeing the correct ratio or not so there is a flexibility with commanded a/f vs timing. So it looks like one might use it creatively to achieve desired timing at any g/cyl and so far this has been the case in my experience. You can see the difference in timing map values commanded vs actual in my logs.

reason#1: Wasn't sure the combo would last or survive in Florida's insane heat with just gasoline.

I wonder if 500rwhp dynojet without water injection would be too much to ask from stock un-gapped piston application, on the hottest day of Florida weather? I've lived here all my life an that day was the hottest day or as hot as the hottest day. And you can see my IAT is like 110*F which is right about max where you would put up with it for this type of day. Cold pipe stayed merely warm which is another good sign. Turbo should be right near the center of it's island so, coolest air possible off the compressor.

Airmass calc was 65lb/min I think, which is a little high even though I was going lean and not out of fuel pump. The sudden jump in VE right near 205KPA to 210KPA surprised me. If the calculation is anywhere near true, the engine is making some 600bhp; 600 * .83 = 498rwhp through an unlocked 4l80e, the most parasitic modernish(overdrive) combo on the planet to put behind a V8 afaik.

You can look around and do some research but I do not think you will get much of a solid answer. It wasn't that I had to find out for myself necessarily; clearly alcohol is superior and it will need to work its way into this build eventually. All cars should wind up flex fuel IMO, what a great option to have. The real reason I had to do it is because I want to drive the car right now, for the last 3 years, and not have it sitting and waiting for me to perfect some kind of amazing fuel system. Instead of waiting I just popped a $99 fuel pump in the tank and started driving to work everything else out more or less before moving on to the aspect of fueling 600+

Also now knowing what i t makes at 3psi, 7psi, etc... we will accurately predict torque vs boost and help to find where the turbo 'runs out' without running it too far off the map or IAT too high during testing.

I think its not a big deal when you look at displacement vs torque, a 2L can make 300ft*lbs of gasoline, so a 4L should handle 600, so the 5.3 should be able to achieve something like 800ft*lbs of torque on gasoline. But that is obviously crazy... right? Well notice we did not mention power. The increase in power is going to create more heat as a byproduct in a short time frame, which is going to negatively influence the gasoline quickly making it dangerous to keep going. That is to say, the stock engine could probably do 750ft*lbs at 3,500rpm on gasoline if you let up before it heats up much. But we live in the age of alcohol so don't be crazy... after 600 or so its time to add alcohol (lets get serious about safety). I am thinking aux fuel cell in the trunk maybe 5 to 8 gallons with E85 on a mixer that I can dial the E10 from primary 15.5gallon fuel tank into roughly ratio of E30 or E40 between the two. Does such a thing exist? It sounds complicated. In reality when I get time to research many months I can safely drive 500rwhp in any weather while I decide how to handle the issue of alcohol safely. No way I am putting alcohol into the factory fuel tank though. Protip: Alcohol is a powerful solvent and anything in an old tank that was insoluble in E10 gasoline sitting on the floor of the tank could suddenly become dissolved and quickly clog the fuel pump and wreck the entire fuel system. So it is something I would do only after dropping the tank and fully cleaning it which may become the option I go for. I could simultaneously reinforce the known weak points of the tank strap area. Still I like the idea of extra capacity fuel cell. Gonna munch on it while I abuse what I assume is an insanely low compression fully worn the #(@*@# out truck engine. I mean it has 150psi but you should see my 15th scanner log, 15.5psi and 12.5:1 air fuel ratio through peak torque and it didn't even twitch on the worst possible day. I bet the bearings all look mint. Not gonna open it to find out.

reason#2: Doesn't make sense to dyno a fresh swap, only to have it blow up months or weeks later and have to replace it (and then need to re-dyno same old).

I knew I could take an engine (any engine) to the dyno immediately and press on it. But some forms of damage take time to build up... for example the oil system could be weak and gradually result with eating up the engine bearings over several months. You wouldn't see that on the dyno in the first few weeks of a swap, but eventually the engine would blow and you would NOT know why, doomed to repeat the same mistake or failure. On that hand, it has nothing to do with power; the installation can simply have a fatal flaw. Its just far more important to me that the installation be bullet proof and reliable than actually make some inane amount of power. Power is just a bonus to having a reliable car in the first place, reliability comes first or you can't even drive it.

By waiting, I have more or less ensured that the combo is a reliable entity, untouched for years exactly the way its been all along. The gaskets have all held perfectly, many many heat cycles so they are 'stuck' down to the engine parts, 'glued' together so to speak. A fresh gasket might be tempted to blow out easily but the old ones are like glue sometimes, know what I'm sayin'? The spark plug wires have almost 30k on them and still look and work great(coming from SBC land, this is remarkable). The boost pressure test(turbo->intake) reveals no boost leaks, even with all the clamps kinda loose and a 20psi test pressure... crankcase is sealed so well you can blow into the vent and put your finger over it and it will hold air like a balloon. hint: use a

supra pcv valve... its pretty amazing how well everything fits together.

Just another day for a truck somewhere

I didn't even check the oil or pop the hood before the dyno day. I just hopped in the car and drove it there like a daily driver you expect to run perfectly, that oil has more than 1500 mileage, and wound up driving it home the same way. And no, I don't have AAA or any kind of towing available. I am not sure what I would have done. I just didn't expect to have any issues... You don't have that kind of confidence in a swap unless you've been driving it every day for years. And i am not gentle, usually its 1st and 2nd though not 3rd very much because 3rd is for the track mph. I bet I can wing it out to ~6600easily on track day for 130-140mph. But rpm can be a deal breaker for oil systems and other things. We will see, I might drop to 4.8L or beef up the valve train a bit. My dream is solid roller of course but that adds unnecessary expense so.. I can't justify the cost of a custom cam. This car needs to maintain itself.

I've never had this engine much over 5400rpm before either. I always shift early 5400ish (setting is like 5100rpm) because there is always a delay and the delay is based on how much power you are making. The more power you make the higher the engine will accelerate before a shift potentially can occur. For example at 3psi if I command shift 5200 I get 5300. But at 15psi you command 5200 you get 5500 sometimes 5600 5700. The delay becomes more pronounced usually, but not always, its kind of random and crazy within some range. I stopped trying to figure it out and just waiting to max power first, then I will dial in the track shift exactly right.

The dyno was the first time she got to stretch her legs to 6200rpm...My street limiter was always 5800 but I think 6200 is fine for my application, maybe even 6500ish. I even tagged the limiter on one of the runs to be sure. RPM was sort of the final test I guess. If it could survive the hottest dyno day possible I suppose it would theoretically survive anything else I can come up with on the street, thats the idea anyways.

So here is a break down. The video tells most of the story but there are some things you should know in additional to the video.

First, I used the lightest spring possible in the gate, 3psi only. This was originally so I can put 87 octane in the engine whenever I feel like it, but I haven't used 87 in a loooong time.

The reason I never changed the spring is that it helps us get a baseline insight to the health of the engine, if we dyno at 3psi it should put out near stock power, plus the boost, minus exhaust/intake manifold(the LS1 intake is worse than the truck or anything for that matter), age/wear (which loosen up the engine and make it more favorable to boost at a slight expense to compression), and 4l80e losses. Next dyno I will def use a bigger spring. Just remember this is my first LS engine and despite them being almost free I still don't want to break it! I am treating this thing like it's the last one on Earth... okay almost. Allllmost like that. The oil gets some mileage let me tell you.

The blue line is, 3 to 4psi with the cutout closed.

red line is 7psi or around that, with the cutout closed. I think eventually I made 400rwhp with the cutout closed and like 10 or 11psi. It just won't make boost with the cutout closed because of EGP and the weak spring or I bet it could make 500 with the silent mode one day with more spring. I really love the 3psi spring though because it sort of protects the engine, so to speak. The fuel injectors already maxed with this weak spring. If I put a slightly stronger spring, it would have the potential to overboost if I accidentally adjust the boost controller wrong or something. At least the way it is now I can't accidentally hurt the engine at any setting. safety first

Orange is about 14.5psi and 500rwhp

![Image]()

Diagnostically, it looks like something is 'happening' at almost exactly 5300rpm on every run. There is a small chance it was just the ignition pickup needed to be moved but I never thought of that during the day. Another possibility is that we are seeing some kind of resonant effect, maybe the ls1 intake has an issue with that rpm range. Another thing is maybe the factory lifters are having trouble staying pumped up. Because I see it happen at 3psi same as 15psi, it isn't anything to do with the timing or tuning since those conditions are extremely far apart and the only unifying factor is the rpm at which the issue seems to occur. My intuition tells me to to upgrade lifters and pushrods, and potentially to an LS6 intake manifold. But if I go through all that I will want the L33 or a 4.8L to finish the car at the same time and add 800rwhp minimum potential. Those heads ain'taver coming off that engine as long as I have a say though. Once was enough. It pulls just fine you don't hear or feel it so maybe it really is just the dyno electronics. We will see... it did not go unnoticed... I am on the case.

I don't think this attributed to the effect but I do believe the boost control solenoid got a bit overheated, and the boost started to meander on some of the pulls. I think that is what was causing it anyways. I've seen it happen on other cars but not on an auto w/ unlocked converter. It never did it on the street to me before in 3 years but it did on the way home a little, so I still think it was just the heat. I recently closed the hood fully so its been getting hot in there, plus it was the hottest day. I keep meaning to relocate the solenoid somewhere cooler but its so rare that things get THAT hot. This was a nice reminder though its on my list....

Here is the 3psi run from HPtuners so you can see how much timing I used and a/f ratio etc...:

Here is the red line (7psi) cutout closed run:

Next, there were a bunch of runs where the boost would simply not go up no matter how much I tried to add duty cycle, they are all 10psi to 12psi I think, will need to check. I will post logs to hptuners website and add them.

Of course I expected this due to the 3psi spring... Nevertheless I absolutely HAD to see what it makes with just 3psi. So I wasn't about to change that spring yet. Third eye: we had many long conversations with ourselves about what spring to have inside that gate come dyno day... .

I had the 10psi spring with me but I didn't want to burn my hands off trying to change it on the dyno.

I usually don't trust the in-car wideband but for these I had no choice, the cutout was making the a/f go lean.

I knew it wasn't that lean because the engine would have melted lmao. At the very least it would have burped up some oil and started smoking. Didn't get a single whif of engine oil the entire time, it was smell less. Except of course for that kind of gasoline smell that gets in your clothes after this sort of thing. I am going to lengthen the cutout and maybe add a muffler to it, something aluminum and maybe also aluminum v-band if I can manage. I wonder how a 40 would sound on that thing. It's been yeaaars since i asked myself this question but, maybe its time to tone things down to something more dramatic.

I could have made a LOT more low end torque by using a couple tricks I am aware of, such as letting it shift from 2nd into 3rd before logging, or using the dyno brake to load the engine, but in the spirit of fairness I thought it best to just do typical 3rd pulls most people are used to seeing on paper, plus it helps us compare to other setups. Just keep in mind the 3psi spring probably wasn't doing it any favors to help it spool. It builds boost faster on the street because the engine can't accelerate as quickly as it does on the dyno, this is important to reconcile with the ignition timing profile, as you can gain a bit of torque/power by using more timing on the dyno due to the faster rate of change of the roller compared to the street, but don't leave it like that because the lower rate of street pulls (rate of change of RPM) will increase cylinder pressure potentially blowing a gasket when things heat up.

I added a tiny bit of timing to some, removed it in others, boost didn't change much and neither did power. Wound up using about 0.7* more timing than I went in with which added 9hp some places so I thought it worthy.

At some point I ran out of ideas and just pulled the vacuum line for the wastegate, around run #12 or #13. I knew on the street this would yield around 23psi of boost! (it had happened once or twice rofl she loves it, for mid-range its perfectly safe because there is plenty of injduty) but I figured on the dyno it wouldn't go so high... and I was right. It hit 15.5psi on the money more or less, gave me that 1psi extra boost to make like 28 more hp, Absolutely maxed injectors of course or I would have kept going. Gota say the engine seems to posses a VERY wide tuning window, it seems happy anywhere from 10 to 12 degrees of timing at 14.5psi and just for curiosity I made the 15.5psi run at 13 to 13.5* to make sure I wasn't missing out on anything spectacular. A 2L engine is very specific, it cant be 8* or 10* it has to be 9* in some spots exactly on gasoline, so this tells me that 5.3L engine is barely working so far. It can handle wayyy more boost on gasoline. I am thinking 20 easy maybe 23 or 24psi will be possible based on what I just saw. As long as I control EGT of course.

but isn't that always the case. Nice to see that Aeromotive stealth pump kicking 500 with a 5/16" line. They say 700bhp is possible so I might just throw some 80's and make 600 soon.That is alot harder to do with 2L because boost is much higher at this power which means fuel pressure is also much higher and that puts a strain on pump output.

I am only using 53psi of fuel pressure base.

HPtuners log, most of them looked like this:

* I am running an

iridium 7 heat range

spark plugs with 0.026" gap

The dyno video has an image error. The correct hptuners scanner file for the dyno run shown is probably this one below, they are similar in boost pressure. If you really care you can count the number of runs and then find the exact run in the log files I will provide.

The turbo still has way more to give, this S364 will flow 850BHP worth of airflow! I can probably squeeze at

least 640rwhp from this baby the way it is with a little alcohol in the mix. Heck it might not even need alcohol, but I am not sure the LM7 is the block for the job.

cough L33 what>? I am fond of water injection but this turbo isn't really big enough for this engine to use water effectively, I would want more like 105lb/min and run it up around 85 to 88lb/min (740rwhp?) with an L33 to justify the installation of a electric, maintenance item water pump, but 700+ just seems crazy in a car like this, I would need to start doing chassis stuff. I am already planning to do some minor things and lets see how that plays out first before we talk 800 to 1000. Because the minute you say 800 I say 1200. So that is why I went with 650 instead of 1300, basically decide whether you want to really "DO" the fuel system with huge lines and 2 pumps and plate the engine to the chassis and stiffen everything... doesn't seem like a good direction for a daily driver I need to drive in six months. So I chose to put a cheap single dash 5AN line on a factory size 5/16 hard line to the factory fuel dead-head fuel rail (so: not optimal lol it can't get much worse) I don't even use an EGT gauge because I am so confident it won't overheat if the air fuel stays down because 5.3L eats up 80lb/min like a 2L uses 80.37735 = 30lb/min, its like baby airflow rate territory for this massive displacement, nothing to worry about in theory.

My original goal for such low boost 14.5psi was to be at least 500 tire using a

"free" engine (LM7 all day w/ 120-180k nearly free around here in SF, just add gaskets, cam and pan goes from engine to engine), reliably on pump fuel gasoline without the added expensive of additives or alcohol and to do so in the hottest part of the day/year under difficult conditions... and she really did pull through, for 3 years almost 30,000 miles so far... it keeps blowing away my expectations. Well actually it is meeting my expectations which was not expected. I don't deserve a car with 500hp thats for sure. The power is just a novelty to me; I don't race or have any interest in racing beyond track data for the sake of backing up the dyno with actual drag performance (they say the track is the real dyno

). The real fun for me though, is the way it handles, sounds, smells, the rough and tumble of it. I love to listen to the cam lope of a V8 with any amount of power... I would drive it with 200hp.

Its a rowdy straight shooter that intimidates when it wants to and purrs like a kitten the rest of the time. I can drive with 1 finger on the wheel, the other holding a camera or a drink. IRS means I can change tire height on the fly without suspension adjustments like an RX7 needs. The chassis is flexible with it's components and works with a wide range of parts. It has aluminum brakes from 300ZX which is a much heavier car so it stops fine from high speeds.

No matter how much power it makes you always want more and there is always a faster car.

So its more what we can do with the least tools and materials at our disposal. The common ore. Stuff that somebody junked into a yard. To them it had low compression and was worn out, to us its been broken in, loosened up and boost ready. It brings a tear to my eye to listen to, but that could just be the exhaust fumes.

In the future I will get a microphone and narrative over these type of video so you can get more information about how I go about these things. But for now this will have to do, I have to focus on research now, back to the lab for some H&E, dapi, dsDNA IHC, those kinds of lab experiments to determine quality of tissue samples for use in cancer study... the car really motivates me to drive to my lab since I can work as many hours as I want in this field. losing track of time while using a microtome is pretty fun A+ highly recommended.

youtube video of the dyno passes:

Thanks for watching! I want to make a 'how eye hptuners' type of video...