wiring up the street rod. I have a pencil style that works like crap. looking for an upgrade. suggestions?

mickleft

24,397 posts

·

Joined 2007

I have a pencil type and a small small torch type along with a good soildering iron.

2,894 posts

·

Joined 2011

One of these!

http://www.acehardware.com/product/.../product/index.jsp?productId=1340440&cp=2568443.2568450.2628094.2629278.2629347

A mechanic changed my life by teaching me the real way to solder connections. Fray out the two connections, put heat shrink over one side, bring the two fan frays of copper together and separately wind them over each other. Then, cut a piece of solder about 1 - 1.5" and fold it over itself into kind of a U. Wind this U around the joint really tight. Then, take a gun like this, heat it up until it is red and then feed a bit of solder on to it until you have a very small puddle. While still holding the gun, while it is red hot, apply the gun to the bottom of the joint. The wound up solder displaces right into the connection and makes a perfect joint every time. This method made wiring my car a blast, easy and accurate as hell. Those pen soldering irons are for PCB's! I will see if I can find a video of the technique.

http://www.acehardware.com/product/.../product/index.jsp?productId=1340440&cp=2568443.2568450.2628094.2629278.2629347

A mechanic changed my life by teaching me the real way to solder connections. Fray out the two connections, put heat shrink over one side, bring the two fan frays of copper together and separately wind them over each other. Then, cut a piece of solder about 1 - 1.5" and fold it over itself into kind of a U. Wind this U around the joint really tight. Then, take a gun like this, heat it up until it is red and then feed a bit of solder on to it until you have a very small puddle. While still holding the gun, while it is red hot, apply the gun to the bottom of the joint. The wound up solder displaces right into the connection and makes a perfect joint every time. This method made wiring my car a blast, easy and accurate as hell. Those pen soldering irons are for PCB's! I will see if I can find a video of the technique.

6,913 posts

·

Joined 2009

Nope, I've had the high output wellers they don't have enough ass for 10 gage wires or soldering three or four wires together. Buy this 400 watt one below, I have one and they work great. Heat up super quick, study tip design and priced right. When soldering automotive wiring you want to get the wiring hot as fast as possible for a quick solder joint. If you have a low power iron the heat will just wick back three or four inches in the wire putting a hurting on the insulation and never getting hot enough.

Here ya go:

http://www.sears.com/craftsman-professional-dual-heat-soldering-gun/p-00927320000P

Here ya go:

http://www.sears.com/craftsman-professional-dual-heat-soldering-gun/p-00927320000P

2,894 posts

·

Joined 2011

Here is what I do:

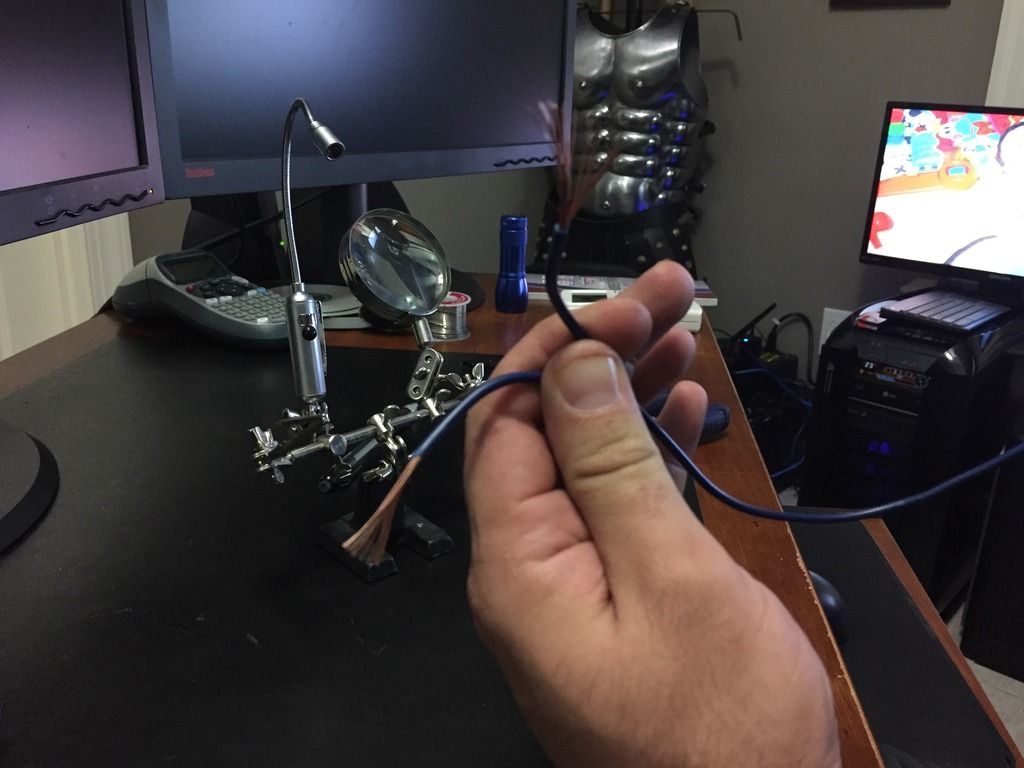

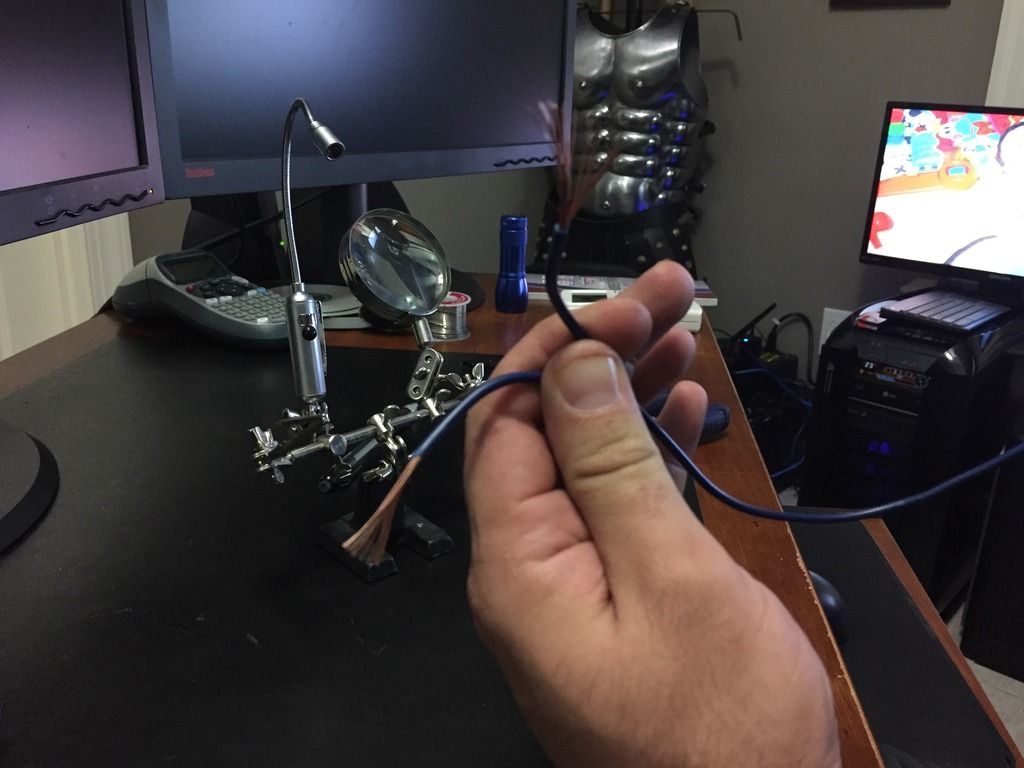

Step 1: Fray the wires

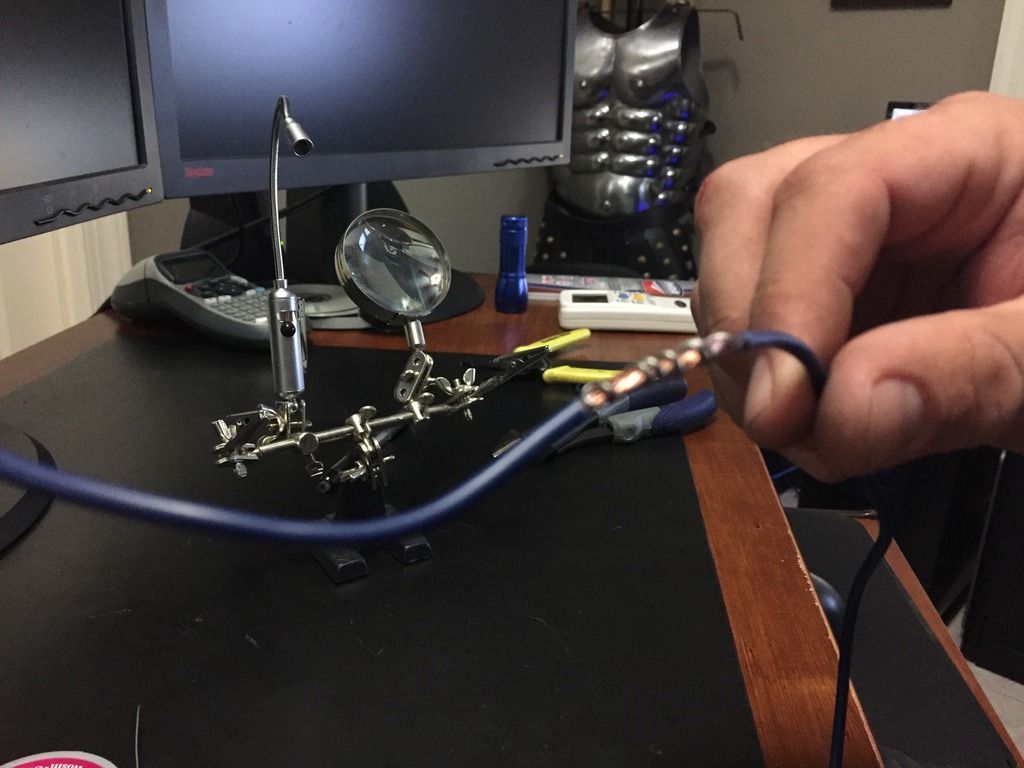

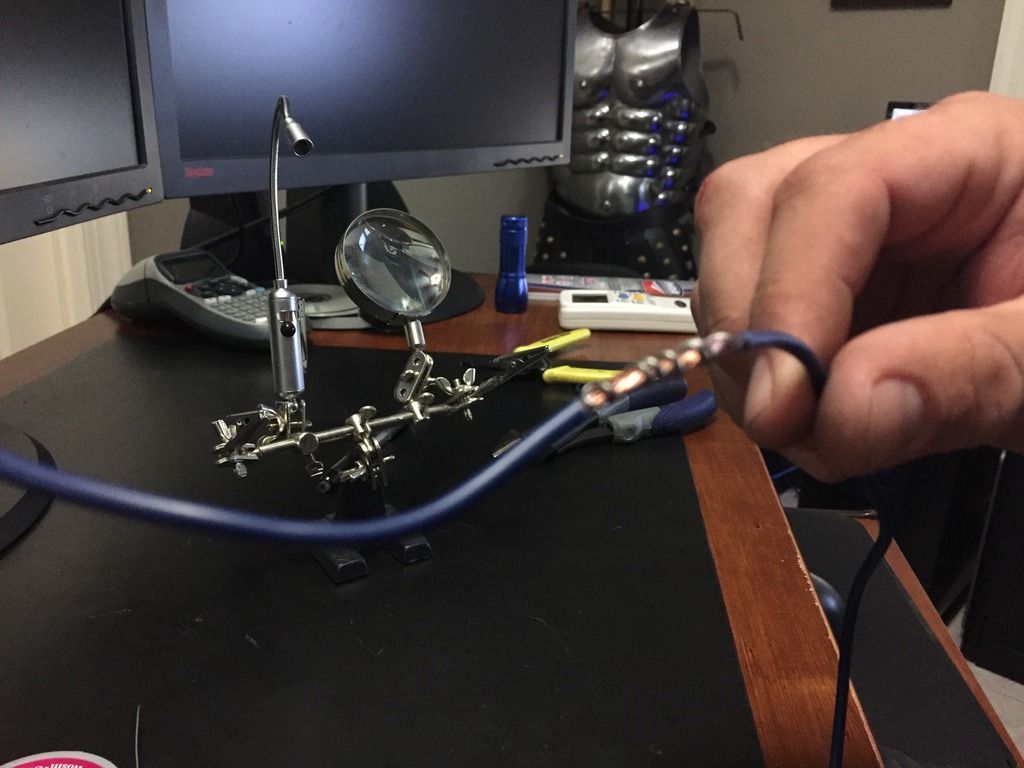

Step 2: Wind them together

Step 3: Cut a piece of solder and form it into a "U"

Step 4: Wind the U around the joint

Step 5: Solder it (I didn't have it tight enough so some fell off but I did this quick) Video

heat shrink it... next!!! Again, I did this video and pictures quick but it is a great method. This only works with a flat tipped gun and not a pen.

Step 1: Fray the wires

Step 2: Wind them together

Step 3: Cut a piece of solder and form it into a "U"

Step 4: Wind the U around the joint

Step 5: Solder it (I didn't have it tight enough so some fell off but I did this quick) Video

heat shrink it... next!!! Again, I did this video and pictures quick but it is a great method. This only works with a flat tipped gun and not a pen.

1,052 posts

·

Joined 2014

I like to get things done in a hurry so I use a MAP gas torch :smt098

533 posts

·

Joined 2005

http://www.amazon.com/Hakko-FX888D-...65-9061733?ie=UTF8&qid=1461762625&sr=8-1&keywords=hakko+fx888+soldering+station

i use this for RC cars and also have used it for big cars too..

i use this for RC cars and also have used it for big cars too..

59 posts

·

Joined 2012

As someone who uses these things daily for the past 15ys (auto electronics and vehicle wiring) and has tried just about every reasonably priced gun and pencil put there, a big +1 on that Hakko model. it gets plenty hot quickly, fully adjustable as well as can be put in a secure mode that locks on one temp.

My main "in car" butane is one of these...

http://www.amazon.com/PSI100K-Super-Pro-Self-Igniting-Cordless-Soldering/dp/B000ICGN38/ref=sr_1_1?ie=UTF8&qid=1461856865&sr=8-1&keywords=PSI100K

Plenty of heat, tips last and not nearly as tempermental as the Power Probe one.

My main "in car" butane is one of these...

http://www.amazon.com/PSI100K-Super-Pro-Self-Igniting-Cordless-Soldering/dp/B000ICGN38/ref=sr_1_1?ie=UTF8&qid=1461856865&sr=8-1&keywords=PSI100K

Plenty of heat, tips last and not nearly as tempermental as the Power Probe one.

21,809 posts

·

Joined 2014

I use several, and that has changed over the years, and changes even now depending

For out in the sticks, or "up that tower" (RF feedlines) you really cannot beat the "big" Weller Butane. But they are WAY too "much" for small wire

http://www.weller-toolsus.com/soldering/irons/butane/weller-wpa2-weller-pyropen-kit.html

![Image]()

The big weller butane is big. It's huge. In fact, it's quite large. They can be had with several sizes of tips, I think the largest is on the order of 5/6 wide chisel. We used them to solder HUGE RF heliax center connectors

Next, go to garage, thrift, "used" stores and find yourself a real by-Gawud soldering IRON. Something from the 50's. The trick here is they are usually only 80-100 watts, which is not much in a "gun" but the "big tip" is the "deal"

I've actually got several of these, and paid less than 5.00 apiece for them

![Image]()

Doesn't need to be "this big" but believe it or not I HAVE one "that big"

![Image]()

Someone above claims the big Weller gun is "not enough". I have no idea what you are doing, there, but you can EASILY solder a pair of 10ga wires with the "big" Weller gun. You MUST wiggle /loosen/ tighten the tip nuts the first time you "get it out" to make sure they are tight. This is an ongoing problem with ALL Weller guns, but once you learn that simple work around, you are good

The D550 seems to have changed over the years, I swear some of the older ones were higher wattage but they do show a D650

Amazon shows them for under 60 bucks

http://www.amazon.com/Weller-D650PK-Industrial-Soldering-Gun/dp/B000TDGI18

![Image]()

But for smaller stuff, no 18--16 wires, a bench "pencil" iron around 60W is fine. THE SECRET HERE is get a large enough tip. GET A LARGE ENOUGH TIP!!! GET A............. get it? And with stuff like the Wellers make CERTAIN you get the RIGHT "correct" tip for the iron!!! Some of those are "trick" magnetic controlled tips, and you have to have the right tip for the iron.

![Image]()

For out in the sticks, or "up that tower" (RF feedlines) you really cannot beat the "big" Weller Butane. But they are WAY too "much" for small wire

http://www.weller-toolsus.com/soldering/irons/butane/weller-wpa2-weller-pyropen-kit.html

The big weller butane is big. It's huge. In fact, it's quite large. They can be had with several sizes of tips, I think the largest is on the order of 5/6 wide chisel. We used them to solder HUGE RF heliax center connectors

Next, go to garage, thrift, "used" stores and find yourself a real by-Gawud soldering IRON. Something from the 50's. The trick here is they are usually only 80-100 watts, which is not much in a "gun" but the "big tip" is the "deal"

I've actually got several of these, and paid less than 5.00 apiece for them

Doesn't need to be "this big" but believe it or not I HAVE one "that big"

Someone above claims the big Weller gun is "not enough". I have no idea what you are doing, there, but you can EASILY solder a pair of 10ga wires with the "big" Weller gun. You MUST wiggle /loosen/ tighten the tip nuts the first time you "get it out" to make sure they are tight. This is an ongoing problem with ALL Weller guns, but once you learn that simple work around, you are good

The D550 seems to have changed over the years, I swear some of the older ones were higher wattage but they do show a D650

Amazon shows them for under 60 bucks

http://www.amazon.com/Weller-D650PK-Industrial-Soldering-Gun/dp/B000TDGI18

But for smaller stuff, no 18--16 wires, a bench "pencil" iron around 60W is fine. THE SECRET HERE is get a large enough tip. GET A LARGE ENOUGH TIP!!! GET A............. get it? And with stuff like the Wellers make CERTAIN you get the RIGHT "correct" tip for the iron!!! Some of those are "trick" magnetic controlled tips, and you have to have the right tip for the iron.

59 posts

·

Joined 2015

Pace sensatemp. Digital iron with settable temp range. You can also get a clamp style iron. I looks like a miniature grilling tongs, so you can clamp both wires with the iron, and tin up with your other hand.

59 posts

·

Joined 2015

Here's a link to the pace accessory I mentioned.

https://www.paceworldwide.com/products/accessories/green-comfort-grip-and-insert-for-60190069p1

https://www.paceworldwide.com/products/accessories/green-comfort-grip-and-insert-for-60190069p1

12,395 posts

·

Joined 2010

I had an RC dude show me how to solder without ruining the rubber casing on the wire.

I rub flux into the wire.

I melt a blob of solder onto the tip of my 80 watt iron.

Touch the molten blob to the fluxed wire, and the wire sucks it in instantly without overheating the plastic housings.

Simple, quick, and clean joints.

I rub flux into the wire.

I melt a blob of solder onto the tip of my 80 watt iron.

Touch the molten blob to the fluxed wire, and the wire sucks it in instantly without overheating the plastic housings.

Simple, quick, and clean joints.

6,532 posts

·

Joined 2013

I rewired my stocker and super stocker. Never soldered a single wire. Don't see the reason why to do it.

1,052 posts

·

Joined 2009

When we were racing R/C cars we always used Ungar soldering irons. They work really well and last a long time. I never solder any wires when wiring a racecar!

2,428 posts

·

Joined 2005

My weller died last week and I replaced it with a Wall Lenk LG400C, it's got two outputs, 400 watt and 100 watt. It works excellent, heats up a lot faster than the old weller and easily does like 12ga splices and heavier terminals. So far it's been a great gun.

1,299 posts

·

Joined 2010

2,742 posts

·

Joined 2010

hakko 936 soldering station. really flexible cord to the power unit, adjustable heat. prob not enough watts for battery cables but any other general wiring will work great.

494 posts

·

Joined 2008

Old style bakelite Weller gun. Not the shitty new ones. The old style ones are heavy duty models. They are a world of difference when soldering wires on a car. The stick/pen ones are for circuit boards and tiny wires

25,280 posts

·

Joined 2006

Old school 50 watt Ungar with big tip from Radio Shack, what I used to build RC battery packs and solder 4 gauge wire after proper tinning, flux is your friend but you need a little.

35,273 posts

·

Joined 2008

Hakko , they are used by Government contracting agencies. That's where I scored mine.

http://www.amazon.com/Hakko-FX888-FX-888-Soldering-Station/dp/B004M3U0VU

This thing is waaaaaaay nicer and far more reliable then anything I had before it.

http://www.amazon.com/Hakko-FX888-FX-888-Soldering-Station/dp/B004M3U0VU

This thing is waaaaaaay nicer and far more reliable then anything I had before it.

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

- posts

- 24M

- members

- 152K

- Since

- 2005

A forum community dedicated to drag racing drivers and enthusiasts. Come join the discussion about racing, builds, pro mods, hot rods, events, turbos, nitrous, superchargers, and more!

Top Contributors this Month

View All

VinnyVette9340

1.3K Replies

70FG

1.3K Replies

Steve.k

1.1K Replies