Suggestion? 582 bbc in a Ford Capri, C.E. two piece motor plates. It's a street car so I gotta have an alternator. I plan on running a belt driven water pump with a serpentine belt on it. I need to mount the alt low because the hood is low. Will it compromise the strength of the plate too much by trimming it out enough to mount a small alternator on the left side. I don't have any experience using these except on a dragster. Any help, recommendations are appreciated. Thanks

Motor plates with an alternator

1 - 20 of 43 Posts

Joined

·

13,036 Posts

Suggestion? 582 bbc in a Ford Capri, C.E. two piece motor plates. It's a street car so I gotta have an alternator. I plan on running a belt driven water pump with a serpentine belt on it. I need to mount the alt low because the hood is low. Will it compromise the strength of the plate too much by trimming it out enough to mount a small alternator on the left side. I don't have any experience using these except on a dragster. Any help, recommendations are appreciated. Thanks

Joined

·

3,031 Posts

Why not adapt the alt to a bracket off the frame, seen several that were run off a standoff bolt type setup on the motor plate and a small tie-rod setup for tension to the frame rail. Maybe that would work..... I wouldn't cut the motor plate out if you can avoid it.

I bought a alternator mount from http://www.jonesracingproducts.com/

They have a number of setups. See if that'll work for you...

They have a number of setups. See if that'll work for you...

Joined

·

1,044 Posts

I welded an extended boss on my Mesierre water pump. Then cut a Cresent shaped slot in the plate to adjust. Mounted the alternator to the pump. Been this way 4 years in a 9.0 car. Never loosens.

Doug

Doug

Joined

·

923 Posts

Depending on what type cooling fan it has you can also mount it backwards if it helps.

Joined

·

22,891 Posts

I cut into my plate for the Powermaster low mount alternator kit that was previously on my setup. Never had an issue with it

Joined

·

4,740 Posts

The serpentine belt is what's going to be a pain in the ass. I've made brackets off of the frame or the plate itself with an adjustable mandrel off the crankshaft. I'd trim the plate as little as possible esp. if its a 2 piece plate. Totally agree with Sean, call Jones.

Joined

·

6,566 Posts

Mines not a serpentine, but it shouldn't matter. I built a bracket and mounted the alternator on the frame rail. Tensioner is made from a couple 3/8" rod ends and some tubing. Works great.

Joined

·

6,030 Posts

Can you post a picture? I need to fit an alternator and a sanden AC pump on a Hemi with motorplate and forward facing turbo headers.I welded an extended boss on my Mesierre water pump. Then cut a Cresent shaped slot in the plate to adjust. Mounted the alternator to the pump. Been this way 4 years in a 9.0 car. Never loosens.

Doug

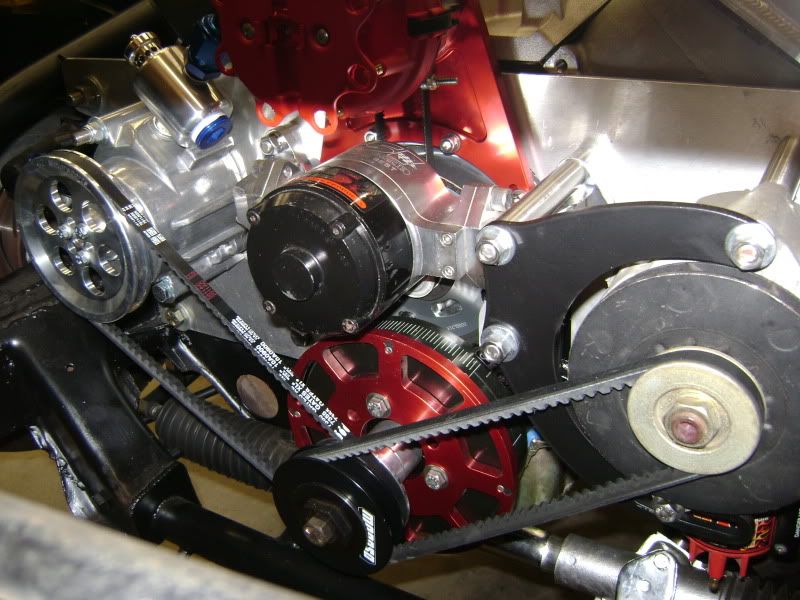

I don't know if this will help because I've never run a meiser pump. But the alternator does sit well below the hood line. You'd have to make an anchor bracket attached to the water pump, so the tensioner has something to hook to. The tensioner is the polished aluminum rod up top. All it requires is two bolt holes in the front plate as an anchor for the bottom bracket on the alternator (the piece I bought from jones), and is black. Works like a charm and does not move at all...

Joined

·

13,036 Posts

On my car I have to use a short water pump. With a short pump and the engine set back as far as I can get it without modifying the firewall I have about 1-1/2" from the pump snout to the radiator. The alternator fits best mounted under the left side of the block. last time I had it together I made brackets to mount it there with a serpentine drive and it worked good. I'm thinkin' I'm just going to have to put the damn thing together and figure it out once it is. There's a lot of room around the engine but not a lot of room in front of it. The car was originally designed for a 1.6L ford engine.

Joined

·

7,144 Posts

Joined

·

51,087 Posts

My front plate is pretty carved up. Seems to be fine

Joined

·

18,123 Posts

No problem. I have serpentine setups on both of my cars. One is a 7500 rpm combo, the other is 8200+, no belt issues. I use the stock GM 105 amp alternators that came with these cars (3rd Gen F-Bodies). I'll try to find some photos.

Joined

·

13,036 Posts

So I got my motor plates today and damn. The rear one is .090" thick steel. Seems thin for a big block but it is a nice looking piece.

Joined

·

3,031 Posts

My rear is only .090 as well steel. Don't sweat it.

You will want some lateral limiters though to stop front/back movement.

You will want some lateral limiters though to stop front/back movement.

Joined

·

18,123 Posts

I don't use a mid plate, front only. I use solid motor mounts to stop the engine/trans from moving forward/backward in the chassis.

Here are a few shots of my alternator mounting, it is low and hidden behind the radiator hose.

Right now it is hanging loose, had to remove a header to get a tube fixed.

Here are a few shots of my alternator mounting, it is low and hidden behind the radiator hose.

Right now it is hanging loose, had to remove a header to get a tube fixed.

Joined

·

13,036 Posts

That's what I need to do. It looks like the plate's been trimmed for the alternator. When I had my car together the last time mine was tucked up under the left side pretty tight I'd like to do it like that again.

Joined

·

3,031 Posts

Whole reason I put a motor and mid plate in was to do away with the motor mounts, get the damn things out of the way of the headers. If you have solid mount motor mounts why bother with the motor plate, just curious.

Joined

·

18,123 Posts

Solid plate gives me places to mount things! Motor mounts are not in the way, Lemmons made awesome headers for my car, no issues with fitment.

1 - 20 of 43 Posts

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

- posts

- 24M

- members

- 152K

- Since

- 2005

A forum community dedicated to drag racing drivers and enthusiasts. Come join the discussion about racing, builds, pro mods, hot rods, events, turbos, nitrous, superchargers, and more!

Top Contributors this Month

View All

VinnyVette9340

1.8K Replies

70FG

1.1K Replies

DeepBrainThrombosis

1.1K Replies