New to this forum, but its nice to see a place where there isn't a million stupid threads on debadging a vehicle. Im here to share my technical knowledge and learn from others.

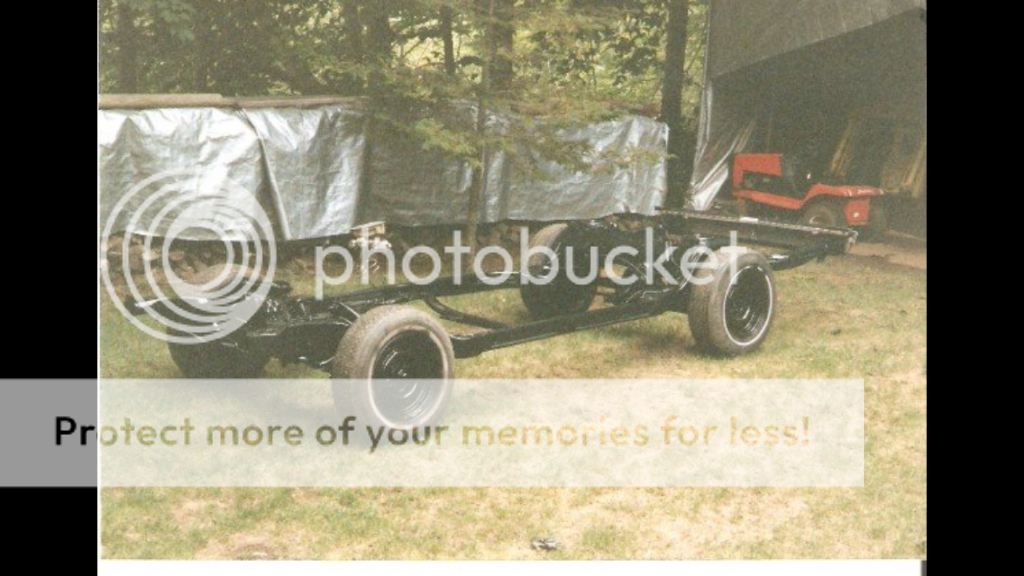

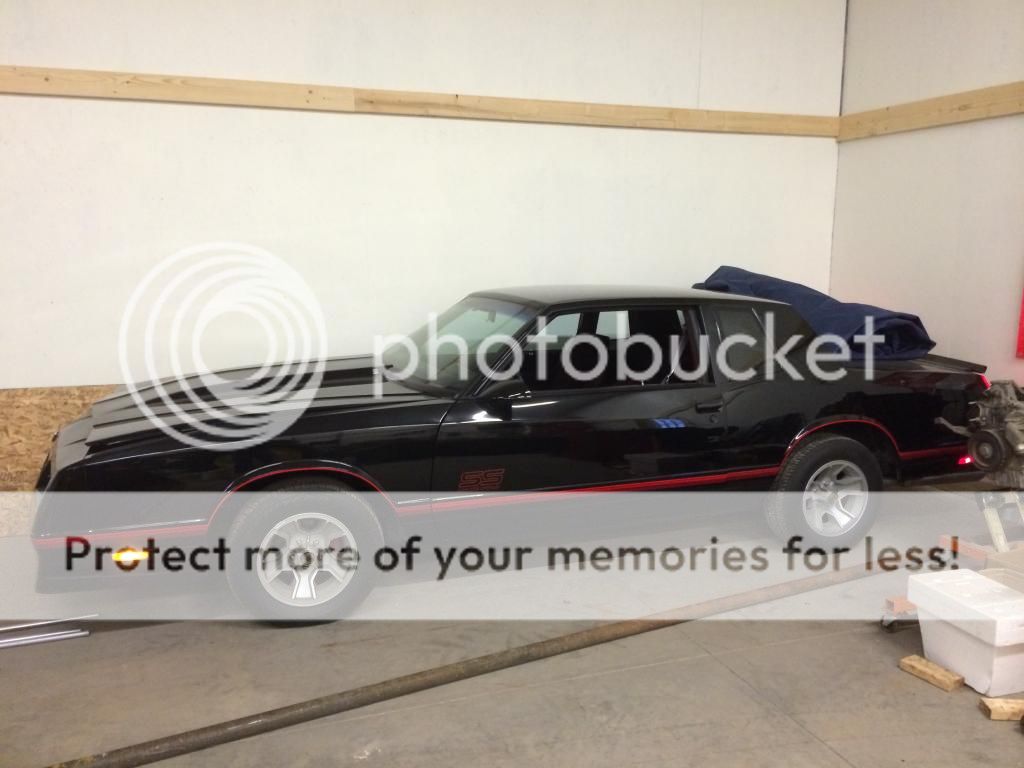

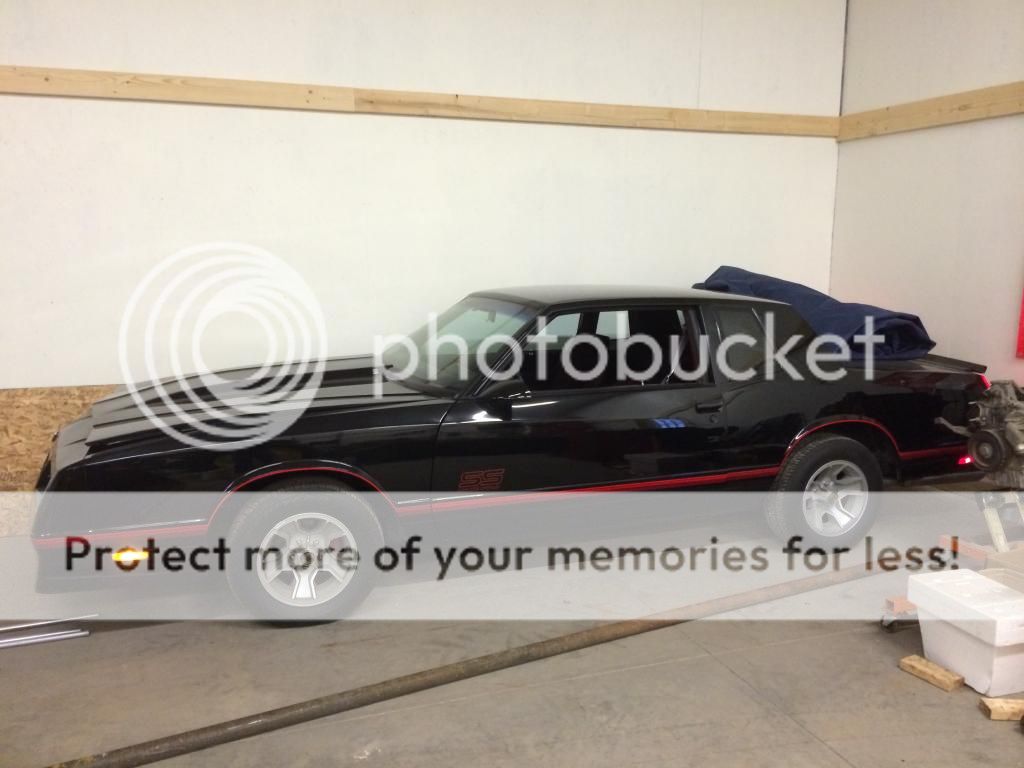

My first car was a 87 Monte Carlo SS that my father and I built from the frame up. I drove it for a year with the LG4 305 and 200-4r and then during my senior year i bought a GMPP 350HO. I drove that through the rest high school (graduated 07) and unfortunately when I was in college, it just sat except for when i came home for vacation becaue my daily driver was a crew cab dually (perfect college vehicle i know).

Fast forward a couple years, I now have a house and a shop and that same old monte carlo sitting in the corner. I put roughly 2-300 miles on it each year because i usually drive the truck wherever i go and when i do drive it i want it to be a little more fun than it is now.

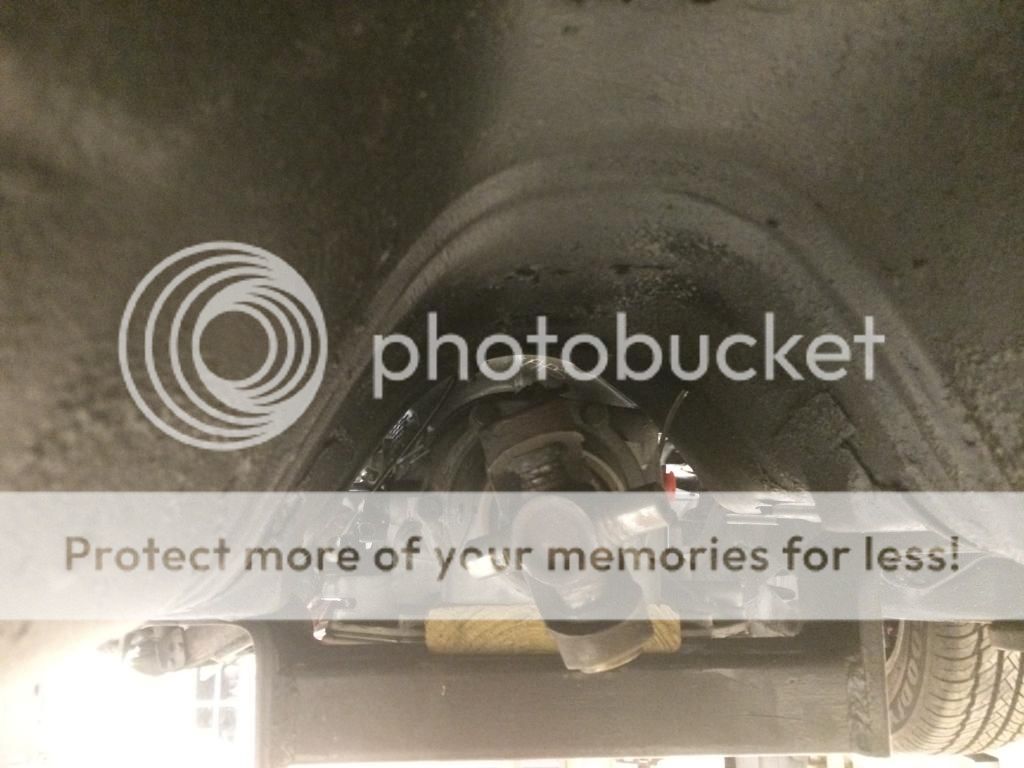

Im usually very busy in the summer, but I did start doing a little work here and there to get it ready for a little healthier engine. Swapped out the 7.5 inch 10 bolt for a quick performance 9" with 3.70s. UMI upper and lower links, cheap 2 inch rear springs to test fit some 275-60-15 M/Ts and 2inch drop spindles up front.

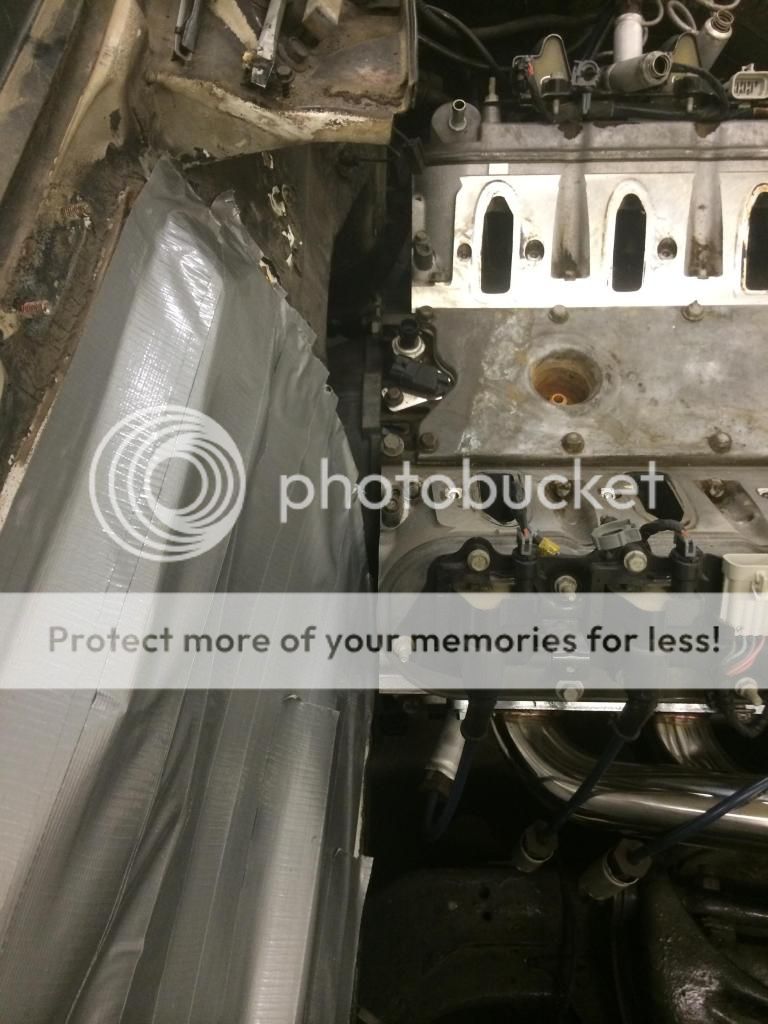

Last night I started to work on it, some more, and will be working on it religiously from this point on through the winter. I've been trying to hold off until I sell the engine but I've become impatient. I thought $3300 for turn key engine with accesories, 200-4r with 2200 stall w/ lockup and 3.73 posi rear would at least get one bite on craigslist but nobody wants it. o well maybe ill find a nice 2wd pickup to throw it in. inner fenders are out and now its brainstorming and decision time. do i want power steering? do i want to keep AC? the car will always stay full power interior, but i'm thinking that if i go through the hassle to keep the things like AC i will be kicking myself when i know the car could be quicker.

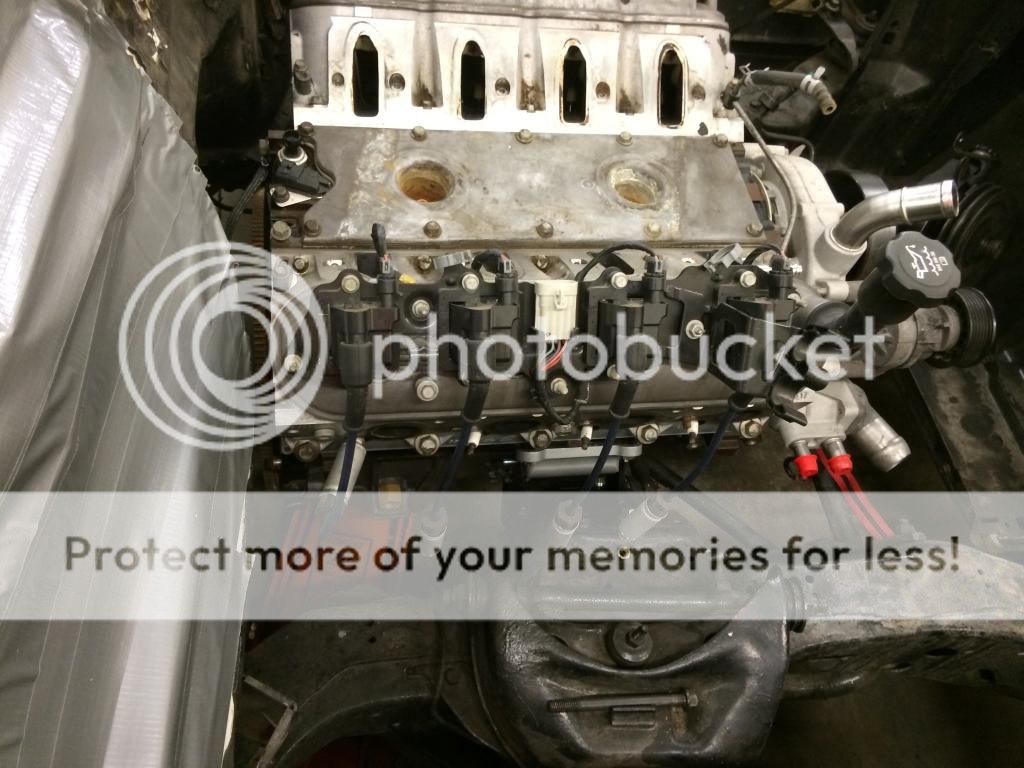

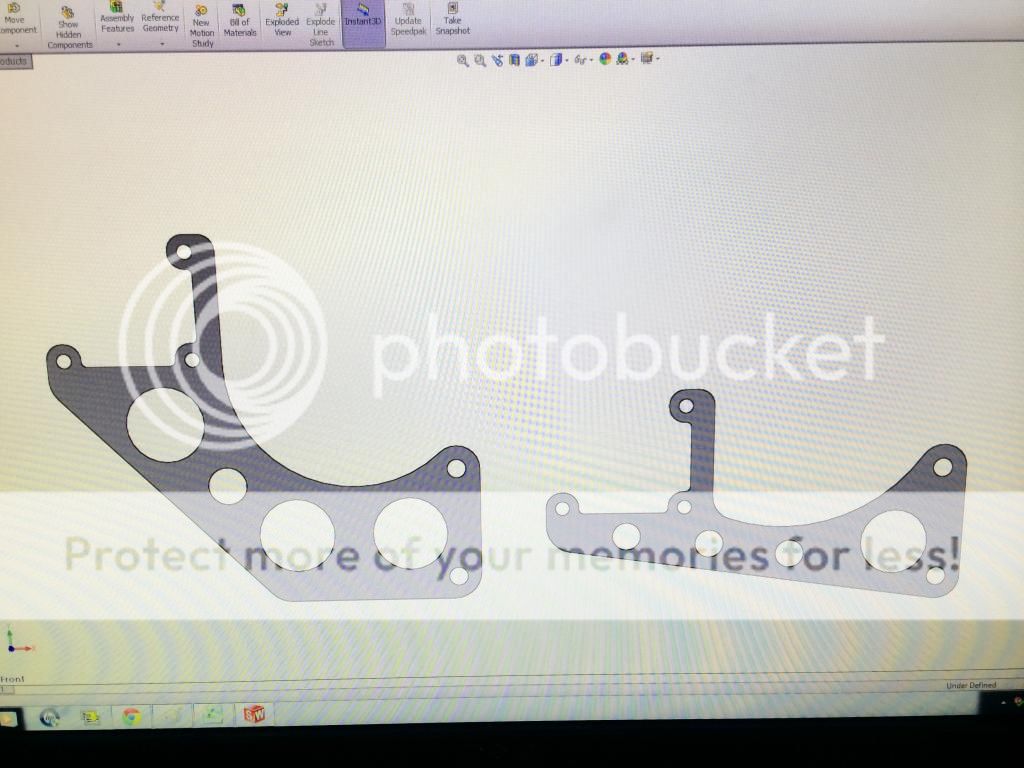

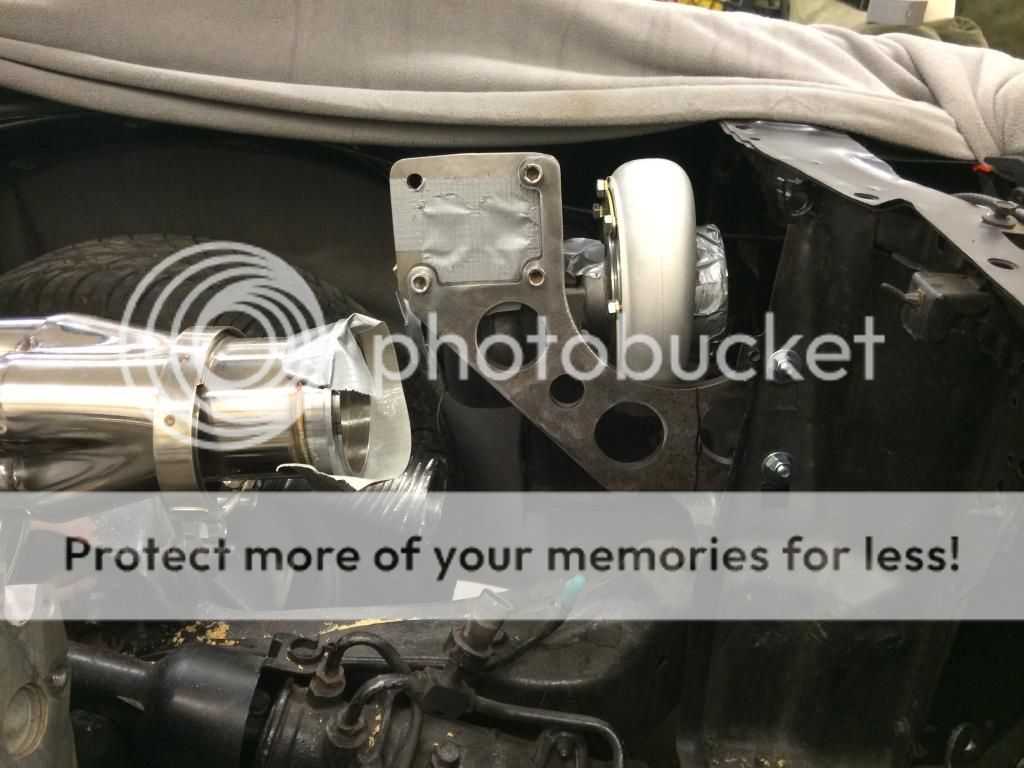

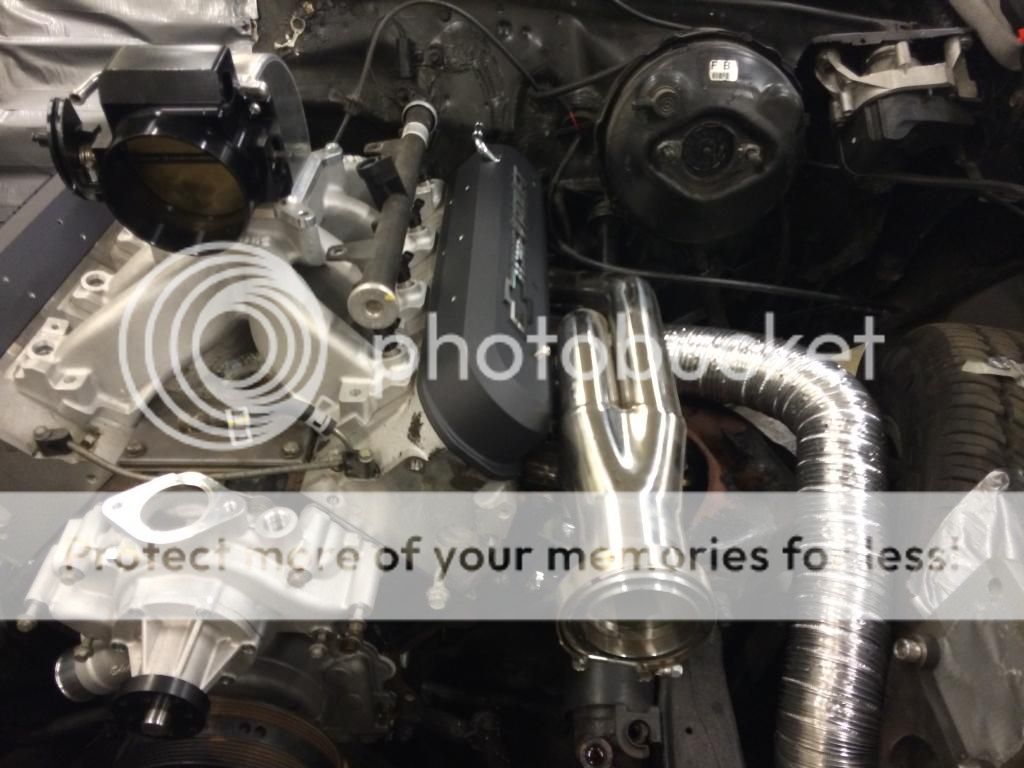

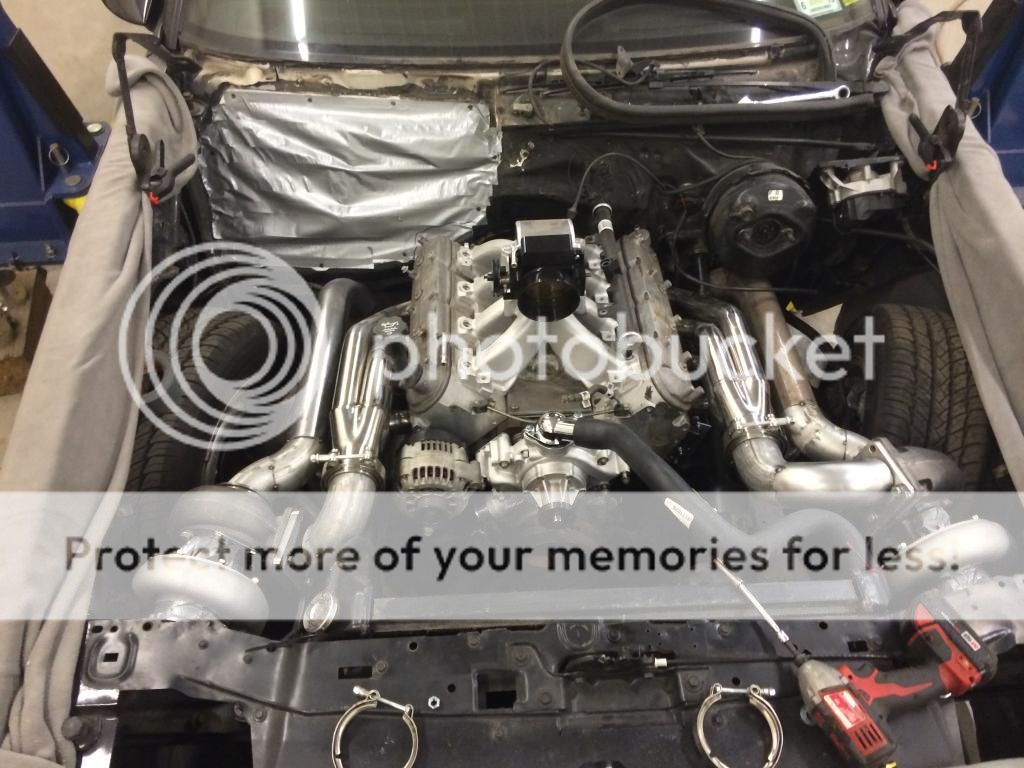

I picked up a low mile LQ4 with 317 heads and 2wd 4L80E out of a 2005 2500HD. grabbed some ebay knockoff forward mount headers, edlebrock intake, intake elbow from 6061.com (beautiful piece) and solid motor mounts from UMI. my goal is to get the new engine and trans sitting in the car by thanksgiving, but it will probably happen before then. I'm getting married a year from now, so between planning/paying for the wedding, this will be a budget build with room to grow. my goal is to be able to work the bugs out next summer and piss my new bride off with a beautiful 2-step launch leaving the ceremony....

Any opinions or input is welcome. Thanks. -Chris

My first car was a 87 Monte Carlo SS that my father and I built from the frame up. I drove it for a year with the LG4 305 and 200-4r and then during my senior year i bought a GMPP 350HO. I drove that through the rest high school (graduated 07) and unfortunately when I was in college, it just sat except for when i came home for vacation becaue my daily driver was a crew cab dually (perfect college vehicle i know).

Fast forward a couple years, I now have a house and a shop and that same old monte carlo sitting in the corner. I put roughly 2-300 miles on it each year because i usually drive the truck wherever i go and when i do drive it i want it to be a little more fun than it is now.

Im usually very busy in the summer, but I did start doing a little work here and there to get it ready for a little healthier engine. Swapped out the 7.5 inch 10 bolt for a quick performance 9" with 3.70s. UMI upper and lower links, cheap 2 inch rear springs to test fit some 275-60-15 M/Ts and 2inch drop spindles up front.

Last night I started to work on it, some more, and will be working on it religiously from this point on through the winter. I've been trying to hold off until I sell the engine but I've become impatient. I thought $3300 for turn key engine with accesories, 200-4r with 2200 stall w/ lockup and 3.73 posi rear would at least get one bite on craigslist but nobody wants it. o well maybe ill find a nice 2wd pickup to throw it in. inner fenders are out and now its brainstorming and decision time. do i want power steering? do i want to keep AC? the car will always stay full power interior, but i'm thinking that if i go through the hassle to keep the things like AC i will be kicking myself when i know the car could be quicker.

I picked up a low mile LQ4 with 317 heads and 2wd 4L80E out of a 2005 2500HD. grabbed some ebay knockoff forward mount headers, edlebrock intake, intake elbow from 6061.com (beautiful piece) and solid motor mounts from UMI. my goal is to get the new engine and trans sitting in the car by thanksgiving, but it will probably happen before then. I'm getting married a year from now, so between planning/paying for the wedding, this will be a budget build with room to grow. my goal is to be able to work the bugs out next summer and piss my new bride off with a beautiful 2-step launch leaving the ceremony....

Any opinions or input is welcome. Thanks. -Chris