Who has done it? Where can i get the bearing to do it at? Turbo application, dont want to have to worry about my thrust bearing as much when building boost etc

nastychevelle

Roller Thrust for ls block

1 reading

nastychevelle

Discussion starter

1,033 posts

·

Joined 2009

- Add to quote Only show this user

Who has done it? Where can i get the bearing to do it at? Turbo application, dont want to have to worry about my thrust bearing as much when building boost etc

2,828 posts

·

Joined 2012

i have one in the works now, it will be available in the next few weeks,

it is designed to work on external oil pump engines as it replaces the stock oil pump, no machining is required to the block, crank or any other part,

it requires a 2 piece timing chain/oil pump drive (rollmaster or similar) as the oil pump drive is replaced with a bearing carrier, it is clearanced to suit double row chain and factory timing covers etc,

some final machining of the spacer is required to set end float of your engine but it is not a tricky job to do and anyone with a lathe can do this.

im only doing this as my engine chewed a thrust in 1 60ft pass, a 1/2 track pass and a full pass..

it is designed to work on external oil pump engines as it replaces the stock oil pump, no machining is required to the block, crank or any other part,

it requires a 2 piece timing chain/oil pump drive (rollmaster or similar) as the oil pump drive is replaced with a bearing carrier, it is clearanced to suit double row chain and factory timing covers etc,

some final machining of the spacer is required to set end float of your engine but it is not a tricky job to do and anyone with a lathe can do this.

im only doing this as my engine chewed a thrust in 1 60ft pass, a 1/2 track pass and a full pass..

5,761 posts

·

Joined 2010

Would that not suggest you have issues elsewhere? There are literally thousands of race motors out there getting the shit beat out of them without using a roller crankshaft thrust bearing. I'm not saying it's not a cool upgrade, but typically when a thrust gets killed (especially in 1 pass), you've got some issue behind the motor (converter/trans).

That said (and assuming all is well with the drivetrain behind the motor), are there really any quantifiable benefits of converting to a roller crankshaft thrust bearing?

That said (and assuming all is well with the drivetrain behind the motor), are there really any quantifiable benefits of converting to a roller crankshaft thrust bearing?

840 posts

·

Joined 2009

Problem can be fixed with stock thrust bearing, add oil pressure to the thrust side of the bearing

Limit converter charge 2

I didn't exactly what you did, fixed mine with these 2

Other way to fix is machine block add rolller behind first main, but it's not needed

Limit converter charge 2

I didn't exactly what you did, fixed mine with these 2

Other way to fix is machine block add rolller behind first main, but it's not needed

21,032 posts

·

Joined 2005

I just pulled my engine down for a rebuild, and noticed a lot of wear on the trans side of the thrust bearing-I was leaning toward it being the converter,

it was a 13" turbo 400 switch/pitch setup-I thought maybe a little ballooning was going on-they mentioned something about charge pressure reduction

I will be using a reg 400 with a balloon plate in the converter, maybe that will be a cure

it was a 13" turbo 400 switch/pitch setup-I thought maybe a little ballooning was going on-they mentioned something about charge pressure reduction

I will be using a reg 400 with a balloon plate in the converter, maybe that will be a cure

3,583 posts

·

Joined 2010

95% of people should not even have to think about this if setup right. 10sec rx is a different ballgame than vast majority here

It would be scary to know how much fuel I burned through my car this summer of 160+mph street pulls at full power this year and alot of trans brake stuff. And my thrust didn't move from its 5 thou setup. Looked new when pulled apart.

No filing or bearing mods of any kind, just transmission setup correctly

It would be scary to know how much fuel I burned through my car this summer of 160+mph street pulls at full power this year and alot of trans brake stuff. And my thrust didn't move from its 5 thou setup. Looked new when pulled apart.

No filing or bearing mods of any kind, just transmission setup correctly

2,828 posts

·

Joined 2012

If you run a external oil pump then there is no reason not to bolt this in and be done with it, if you don't then mod the stock thrust or get the block and crank machined to take a Torrington behind the first cap.

7,188 posts

·

Joined 2011

We did some pressurized thrust mods when I was at KUP. They seem to work very good for a plane bearing setup. We had one come back in for freshen up that had about 200 passes on it and still had good thrust clearance but did have some heat checking. There are others that will say all thrust bearings are not created equal. The pic below is a BBC vs LS thrust and obviously bigger is better but if you look closer the BBC is an ACL design I use in all the engines I build and it doesn't just feed some oil to the thrust side like the other bearing but maintains the outer edge to keep a hydrodynamic wedge of oil between the thrust bearing and the crank's thrust surface. It also has indentions at both sides of the parting line to feed oil to cool the thrust surfaces. These are also 3/4 groove bearings which I have been very successful with also. The new Billet SBC I am working on uses the BBC mains.

![Image]()

Not much difference, LOL

![Image]()

Not much difference, LOL

5,791 posts

·

Joined 2012

Early on, we had thrust bearing issues with Turbo Buicks. After engine builder, trans builder and torque converter builder blame game, I started looking closer at the crankshaft and found that if it was reground, the thrust face looked like a saw blade. I just couldn't get my crank grinder to quit "touching/trueing" the thrust face. Out came the 500grit to 1500 grit paper to clean up the surface. No more thrust issues.

So, if your crank has been remachined, look closely at the thrust surfaces. You will be amazed at the finish. With a magnifying glass it looks like a buzz saw! Polish it out by hand. 30 minutes of work and it'll save your thrust bearing.

So, if your crank has been remachined, look closely at the thrust surfaces. You will be amazed at the finish. With a magnifying glass it looks like a buzz saw! Polish it out by hand. 30 minutes of work and it'll save your thrust bearing.

2,828 posts

·

Joined 2012

My crank is a Callie's ultra billet polished like a mirror.. It's defiantly not rough

157 posts

·

Joined 2006

3,583 posts

·

Joined 2010

So what did you do to that hurt it? Did you spin a stator tube or somethjng?

2,828 posts

·

Joined 2012

220psi converter pressure... for some reason the box picked up 140psi when it was fitted to the car..

nastychevelle

Discussion starter

1,033 posts

·

Joined 2009

This is how im thinking about doing mine, also hitting the crank with some sand paper to smooth it out like mentioned.

![Image]()

As far as converter charge pressure goes, im going to wire in a pressure sensor and a nitrous purge solenoid on the cooler circuit. Where when the sensor sees above a set pressure it triggers the purge solenoid to open returning fluid to the pan and regulating pressure in the cooling circuit.

As far as converter charge pressure goes, im going to wire in a pressure sensor and a nitrous purge solenoid on the cooler circuit. Where when the sensor sees above a set pressure it triggers the purge solenoid to open returning fluid to the pan and regulating pressure in the cooling circuit.

2,427 posts

·

Joined 2009

Hutch's pressure relief valve is $100, Tee on the lower cooler line with a fitting tapped into the pan or governor cover, simple inexpensive

2,828 posts

·

Joined 2012

i have a pressure relief valve and a spool up dump valve now but still not going to take the chance again when you can bolt something in and fix the issue

5,761 posts

·

Joined 2010

Serious question:

Lets say we do the little file mode at the parting line of the bearing to feed a little oil to the thrust. If there is still a major issue behind the motor pushing the crankshaft forward, will it actually save the thrust face on the crank and the bearing itself, or will it just lessen the amount of damage that will inevitably ensue?

Lets say we do the little file mode at the parting line of the bearing to feed a little oil to the thrust. If there is still a major issue behind the motor pushing the crankshaft forward, will it actually save the thrust face on the crank and the bearing itself, or will it just lessen the amount of damage that will inevitably ensue?

2,828 posts

·

Joined 2012

i have no idea, im not willing to take the risk either

first drawings are done

![Image]()

![Image]()

first drawings are done

2,855 posts

·

Joined 2008

ERL designed and installed a thrust system similar to this on my motor over 3 years ago. I still run converter pressures over 220# at times and never see an issue.

You can put the pressure relief valve in but it reduces the hit from the converter. Had a friend last year with thrust problems that was advised to put in a relief valve that was set to low IMHO and lost over a tenth in the 1/8th.

I have used bearings with all kinds of modifications to the bearing over the years. While i'm sure they help the torrington thrust bearing took care of the issue and my bearings always look like new when I freshen up.

You can put the pressure relief valve in but it reduces the hit from the converter. Had a friend last year with thrust problems that was advised to put in a relief valve that was set to low IMHO and lost over a tenth in the 1/8th.

I have used bearings with all kinds of modifications to the bearing over the years. While i'm sure they help the torrington thrust bearing took care of the issue and my bearings always look like new when I freshen up.

2,828 posts

·

Joined 2012

Thanks for the reply, interesting you run the high converter pressures still,

I thought that the relief valve would take something away from the converter in the hit,

I have got a adjustable relief valve and spool dump valve now so have some experimenting to do

I thought that the relief valve would take something away from the converter in the hit,

I have got a adjustable relief valve and spool dump valve now so have some experimenting to do

2,828 posts

·

Joined 2012

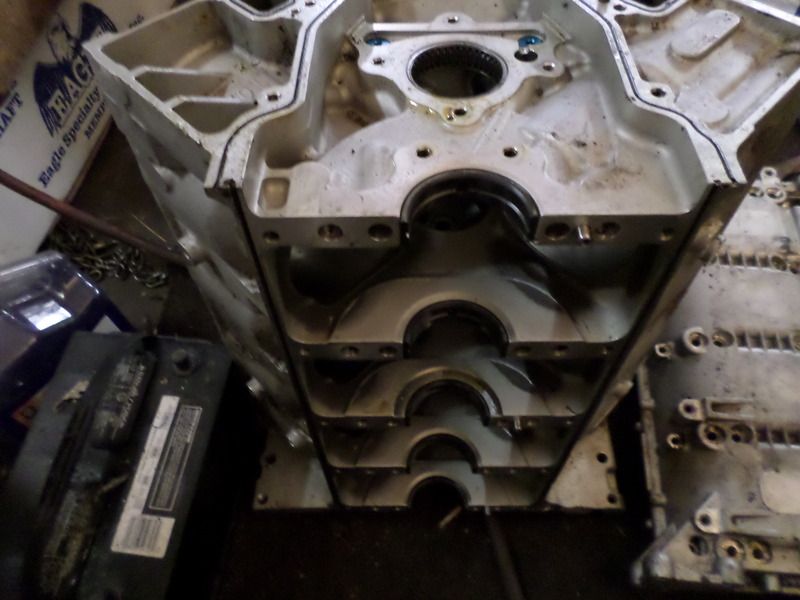

final revision is off the mill ill have it test fitted in the next few days and providing no issues ill get 10 run off.. ill be on a plane to the USA on the 15th and can bring them with me,

![Image]()

![Image]()

21,032 posts

·

Joined 2005

I got all my engine parts back from the machine shop, and meas. the old thrust bearing-it was warn .015 thinner than the orig., so I will be doing

some preventive work-just changing to a new converter will help, and I will add a relief valve to control charge pressure

some preventive work-just changing to a new converter will help, and I will add a relief valve to control charge pressure

2,828 posts

·

Joined 2012

Pricing is $595usd, Ill be in Dallas, Oklahoma and possibly Arizona for the last half of Feb, can also ups them when I arrive

1,583 posts

·

Joined 2007

Although the design is very interesting and should work well.... Wouldn't a lot of the guys having this issue and also having an external oil pump be running a jesel belt drive? In which case this design will not work?

2,828 posts

·

Joined 2012

If they are running a belt drive then they can Machine the block and crank to get a bearing in there..

I don't run a belt drive so no problems fitting it

I don't run a belt drive so no problems fitting it

nastychevelle

Discussion starter

1,033 posts

·

Joined 2009

So what are you doing in the typical thrust bearing spot? Still using a normal bearing? or something special?test fitted, ready to do a run of them,

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

1,320 posts

·

Joined 2009

Very nice!

You will be in DFW tuning, what ECM's will you be tuning?

You will be in DFW tuning, what ECM's will you be tuning?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

- posts

- 24M

- members

- 152K

- Since

- 2005

A forum community dedicated to drag racing drivers and enthusiasts. Come join the discussion about racing, builds, pro mods, hot rods, events, turbos, nitrous, superchargers, and more!

Top Contributors this Month

View All

VinnyVette9340

1.6K Replies

70FG

1.2K Replies

Steve.k

1.2K Replies