Anyone use them? I just bought a set for my 438 TT build. My only concern is the 2.0" journal vs the 2.10" I was going to use. With the 4.08" stroke and 2.10" journal I would have had .289" worth of overlap. Now that I am using a 4.05" stroke and 2.0" journal, I only have .254" of overlap. How concerning is that to you guys considering the application which is 7000rpm and 1250rwhp.

PWR_Andy

Manley 300M rods

1 reading

PWR_Andy

Discussion starter

222 posts

·

Joined 2010

- Add to quote Only show this user

Anyone use them? I just bought a set for my 438 TT build. My only concern is the 2.0" journal vs the 2.10" I was going to use. With the 4.08" stroke and 2.10" journal I would have had .289" worth of overlap. Now that I am using a 4.05" stroke and 2.0" journal, I only have .254" of overlap. How concerning is that to you guys considering the application which is 7000rpm and 1250rwhp.

49,855 posts

·

Joined 2005

short faituge life. As long as you keep it away from deformation and working stress levels, they will last indefinately.Not so sure I think I like them for high power motors. Really hard stiff material. Lots of guys use them with sucess though.

1,993 posts

·

Joined 2009

More questionable info from Collins....

The only real reason 300M can't meet or exceed the strength and fatigue resistance of 4340 is that the metallurgist is screwing up....and I doubt it.

300M is a variant of 4340 and was created to do one major thing metallurgically. Let's see if Collins has any idea what that is.

I think Collins is confusing 300M with an alloy that does have fatigue life issues.

The only real reason 300M can't meet or exceed the strength and fatigue resistance of 4340 is that the metallurgist is screwing up....and I doubt it.

300M is a variant of 4340 and was created to do one major thing metallurgically. Let's see if Collins has any idea what that is.

I think Collins is confusing 300M with an alloy that does have fatigue life issues.

49,855 posts

·

Joined 2005

http://www.google.com/url?sa=t&rct=.../chapter06.pdf&ei=idagTsqEMoXm0QHyhPCQBQ&usg=AFQjCNGaDiAl29ubshgL6CproLFb7ZEHHQ

When you get done reading that, you'll have a better understanding as to why denser harder alloys aren't always the best idea for cyclically loaded parts.

When you get done reading that, you'll have a better understanding as to why denser harder alloys aren't always the best idea for cyclically loaded parts.

1,993 posts

·

Joined 2009

:smt102...shouldt...

Quick Googling is not the pathway to materials science nirvana.

95 posts

·

Joined 2009

Yep, figured that. He seems to know everything about everything. Never have I seen such a knowledgable person on the internet. Most people know a lot about a little, but not this guy, he knows it all. Maybe his name should be changed to the 'oracle'..........

1,780 posts

·

Joined 2011

300m is an excellent material for high stress applications, it has greater memory and elasticity compared to 4340, we use it in high end axle components in rockcrawling applications, basically it can twist alot farther and not deform. where 4340 fails, 300m does not, you start breaking other shit..

1,993 posts

·

Joined 2009

In more scientific terms, the yield strength is higher, and so is the elongation....we use it in high end axle components in rockcrawling applications, basically it can twist alot farther and not deform.

"Memory"....that's a new one....

9,819 posts

·

Joined 2011

So is that why it's used in billet input shafts since they see a lot of twist/pressure?

1,780 posts

·

Joined 2011

talking scientifically gets confusing unless you understand all the nomenclature/physics involved, there is a good thread on pirate 4x4 on material properties of 4340 vs 300m.. thinkin' it would make a killer crank.

1,993 posts

·

Joined 2009

The alloy getting mentioned a lot for cranks is EN30B.

A shade less carbon and a fair amount more nickel. Lower ultimate strength, but very very tough.

A shade less carbon and a fair amount more nickel. Lower ultimate strength, but very very tough.

1,092 posts

·

Joined 2007

Why do some use aluminum rods? I thought it was to soften the shock loads. 300m is great for torsional strain but I'm not sure about the tensile or compressive strains

1,993 posts

·

Joined 2009

300M is just fine for all kinds of loads. Shaft twist generates shear loading that 300M and 4340 both handle well. There are alloys that may exceed those in several areas, but usually they are ghastly expensive and/or the mill won't sell you any quantity less than a whole ingot.

Straight aluminum alloys are much less stiff than steels (approximately one-third as stiff). That is NOT true of Al alloys with composite reinforcement. The obvious reason for either is weight savings.

However the intrinsic stiffness being so much lower is offset by the fact that the rod is so fat (compensating for the loss of tensile strength). So there is a delicate balancing act there. I have not run the math personally but I think the premise seems reasonable that the aluminum rod can absorb some of the pulse and soften the blow to the crank pin.

Straight aluminum alloys are much less stiff than steels (approximately one-third as stiff). That is NOT true of Al alloys with composite reinforcement. The obvious reason for either is weight savings.

However the intrinsic stiffness being so much lower is offset by the fact that the rod is so fat (compensating for the loss of tensile strength). So there is a delicate balancing act there. I have not run the math personally but I think the premise seems reasonable that the aluminum rod can absorb some of the pulse and soften the blow to the crank pin.

12,591 posts

·

Joined 2009

Can you explain the differences in 300M vs M300, vasco 300, A340, and not sure what hytuff is? I've already broke a 300m input how much better is Vasco300M is just fine for all kinds of loads. Shaft twist generates shear loading that 300M and 4340 both handle well. There are alloys that may exceed those in several areas, but usually they are ghastly expensive and/or the mill won't sell you any quantity less than a whole ingot.

Straight aluminum alloys are much less stiff than steels (approximately one-third as stiff). That is NOT true of Al alloys with composite reinforcement. The obvious reason for either is weight savings.

However the intrinsic stiffness being so much lower is offset by the fact that the rod is so fat (compensating for the loss of tensile strength). So there is a delicate balancing act there. I have not run the math personally but I think the premise seems reasonable that the aluminum rod can absorb some of the pulse and soften the blow to the crank pin.

1,993 posts

·

Joined 2009

300M is a modified 4340. Some people call it "super 4340" and treat it exactly like 4340. That would be the WRONG thing to do. The alloy additions in 300M move some of the heat treating ranges around and so does the strength and toughness. Each alloy needs it own process to perform to its fullest.

Most high-end shops would know that, but a lot of racing parts come from mom 'n pops that don't have any metallurgy background so they rely on what they're told. They may or may not inspect the shafts for hardness when they come back from the treater to make sure they got what they asked for. They may or may not ultrasonically test the parts before or after heat treating to make sure there wasn't a defect in the bar to start with. They may or may not even know truly what they are buying. Grabbing a bar of metal and heading off to the shop can lead to very sporadic results.

Now, as for the input shaft in question, can you tell me what the fracture looked like? Was it simply twisted off straight, or was it a 45 degree angle fracture? That can tell you a lot right off the bat.

As for Vascomax: these are known as "mar-aging" steels and have a totally different hardening mechanism than 4340 or 300M. It has a very high nickel content and is one of the absolute wicked toughest alloys there is, period. However, one thing that comes up over and over again with Vascomax and the like is that they do not have great fatigue life when put in a loading situation where the stresses reverse constantly (like say a rod or wrist pin). Put it in tension or compression and leave it there, it can take all kinds of hell. But alternate the stresses back and forth and the story is, it doesn't last. This is mentioned in the book "engineer to win" where he says something to the effect of "the dumpsters of every race shop are littered with maraging parts that failed". I myself have not worked with Vascomax and I am trying to understand why the fatigue properties are questionable. For an input shaft, I don't know if it's the answer. It might be OK because the loads are primarily in one direction.

Hope this helps. More commentary later.

Most high-end shops would know that, but a lot of racing parts come from mom 'n pops that don't have any metallurgy background so they rely on what they're told. They may or may not inspect the shafts for hardness when they come back from the treater to make sure they got what they asked for. They may or may not ultrasonically test the parts before or after heat treating to make sure there wasn't a defect in the bar to start with. They may or may not even know truly what they are buying. Grabbing a bar of metal and heading off to the shop can lead to very sporadic results.

Now, as for the input shaft in question, can you tell me what the fracture looked like? Was it simply twisted off straight, or was it a 45 degree angle fracture? That can tell you a lot right off the bat.

As for Vascomax: these are known as "mar-aging" steels and have a totally different hardening mechanism than 4340 or 300M. It has a very high nickel content and is one of the absolute wicked toughest alloys there is, period. However, one thing that comes up over and over again with Vascomax and the like is that they do not have great fatigue life when put in a loading situation where the stresses reverse constantly (like say a rod or wrist pin). Put it in tension or compression and leave it there, it can take all kinds of hell. But alternate the stresses back and forth and the story is, it doesn't last. This is mentioned in the book "engineer to win" where he says something to the effect of "the dumpsters of every race shop are littered with maraging parts that failed". I myself have not worked with Vascomax and I am trying to understand why the fatigue properties are questionable. For an input shaft, I don't know if it's the answer. It might be OK because the loads are primarily in one direction.

Hope this helps. More commentary later.

6,700 posts

·

Joined 2006

racemod said:Yep, figured that. He [collinsautomotive] seems to know everything about everything. Never have I seen such a knowledgable person on the internet. Most people know a lot about a little, but not this guy, he knows it all. Maybe his name should be changed to the 'oracle'..........

I thought that same thing years ago... but he's a decent guy, really.

Thanks for the spot-on metallurgy info SuperCooper!

9,666 posts

·

Joined 2010

So Supercooper... Talk to us about how 300m would react differently between torsional loads and compression/stretch loads. Would it react differently?

1,993 posts

·

Joined 2009

Not much difference.

There is no "voodoo" with torsional loads, just go take some time looking at the torsion formula and how it applies to shafts. So all your normal properties like yield and ultimate strength, stiffness, etc. are all the same, no special set of data is required to figure it out.

The thing that does separate torsional loads (and the resulting movement / strain) is that they are not equally distributed like they generally are with simple tension and compression loads where you just take the load and divide it into the area to figure the stress.

The torsion formula tells you that the stress (which just happens to be in shear actually) is linear with respect to radius. The highest stress is on the outer skin of the shaft.

This is why, when you're making splined shafts, you need to be very careful about how you cut your splines and how they're transitioned into the shafts with nice radii and no sharp corners. Unless there is a defect in the meat of the shaft, you look to the surface for the signs of problems.

Hope that makes sense. The stress state changes with torsion. The material properties don't.

There is no "voodoo" with torsional loads, just go take some time looking at the torsion formula and how it applies to shafts. So all your normal properties like yield and ultimate strength, stiffness, etc. are all the same, no special set of data is required to figure it out.

The thing that does separate torsional loads (and the resulting movement / strain) is that they are not equally distributed like they generally are with simple tension and compression loads where you just take the load and divide it into the area to figure the stress.

The torsion formula tells you that the stress (which just happens to be in shear actually) is linear with respect to radius. The highest stress is on the outer skin of the shaft.

This is why, when you're making splined shafts, you need to be very careful about how you cut your splines and how they're transitioned into the shafts with nice radii and no sharp corners. Unless there is a defect in the meat of the shaft, you look to the surface for the signs of problems.

Hope that makes sense. The stress state changes with torsion. The material properties don't.

7,487 posts

·

Joined 2007

http://www.race-dezert.com/forum/showthread.php/89838-Why-300M

here,s another thread with some good info on 300M and some guys who have experience with it , seems its quite popular for rock crawling and quads and such for axles

here,s another thread with some good info on 300M and some guys who have experience with it , seems its quite popular for rock crawling and quads and such for axles

25 posts

·

Joined 2012

I know this is a super old thread, But I am sitting on a new set of 300M rods for a gen III hemi project. The car will be supercharged and ideally make 1000 at the crank. Does anyone have an opinion on whether these will work? They look exactly like the picture posted above from PWR Andy.

Thanks for any help.

Thanks for any help.

1,780 posts

·

Joined 2011

Dont leave us hanging bro, pics...

My cnc guy said 300m is basically a super pure form of 4340, a nifty thing is it doesnt warp when heat treating like 4340 does.

My cnc guy said 300m is basically a super pure form of 4340, a nifty thing is it doesnt warp when heat treating like 4340 does.

6,394 posts

·

Joined 2013

-----------------------------------------------------------------------------------------------Dont leave us hanging bro, pics...

My cnc guy said 300m is basically a super pure form of 4340, a nifty thing is it doesnt warp when heat treating like 4340 does.

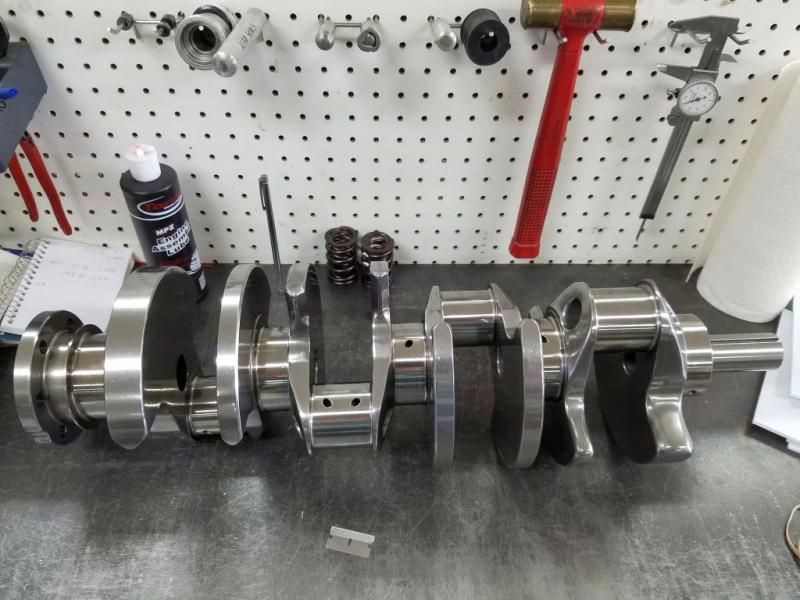

Came 2 or 3 weeks ago. Bryant billet. High speed oiling, fully counterweighted, knife edged and REM polished. Easily the nicest crank I have ever bought.

4.125" stroke. Going in a 468-470ci Pontiac twin turbo.

1,165 posts

·

Joined 2011

Most of the high end cranks over here are made from EN30B, since the '80's IIRC, mostly high revving 4 pot stuff. Very expensive.

1,012 posts

·

Joined 2013

From Tom Molnar on 300m rods.

And his thoughts on H Beam vs I BeamOk, here is the 300M story. A lot of people think 300M is some sort of super alloy with magical properties. The truth is 300M is simply 4340 with vanadium added and a higher silicon content. This change allows the material to be hardened to a higher level. Several years ago I looked into making rods out of 300M and hired an independent testing lab to conduct some tests. The process they used was to make several samples of both 300M and 4340 and heat treat them to increasingly higher hardness levels starting at 34 Rockwell then test them in a fatigue until they failed. In every test, the 4340 had a much better fatigue life until the hardness reached a level near 50 Rockwell which is where the 300M performed better. The problem with this is, no one is heat treating connecting rods to this level because the rod becomes much more difficult to machine. The bottom line is, 300M sounds like a good deal and in some cases it can be but not at the range connecting rods are heat treated to. Something else I found to be interesting is, a couple of years after we did this test, I found out Carrillo did the same test using a different lab and they had the same results.

The I-beam vs H-beam debate rages on and some people will not agree with this but here we go. First off, a little about my background, I have been designing connecting rods for over 35 years including I-beam, H-beam and Parabolic beam configurations. I not only was one of the two people who started Oliver Racing Parts, I designed all of their rods, tooling, fixtures, wrote every CNC program they ever used to make a rod or crankshaft as well as running the company until I left in 2005.

Almost all OEM rods are made as an I-beam not because they are stronger, but because it makes them easier to forge or cast. It is a cost issue not a strength issue for them. Keep in mind that most OEM engines are designed to go to the grocery store and take the kids to school so in these applications, they work fine. The way the OEM companies look at it, If $1 can be saved on a connecting rod and you make millions of them, it starts to add up to real money.

Personally I like the look of an I-beam rod and they are easier and less expensive to machine. When I started Molnar Technologies, I had a clean sheet of paper and designed our rods based on the best strength to weight ratio. To give you an idea of the forces on connecting rods, we have to understand how the loads are applied. When the fuel is burning, it pushes on the piston which in turn, pushes on the rods. Most everyone knows this part but what happens next is the piston is trying to drive the wrist pin though the center of the rod. With an I-beam configuration, you have the two large beams on the sides and the thin section directly below the wrist pin. The problem is the large beams are not directly below the wrist pin which means the thin section in the middle is trying to carry all of the load. As an I-beam becomes overloaded, the thin section will crush and the big beams on the side will split out like a banana peel. Yes, I have seen this and it is the reason Oliver changed to a Parabolic design which handles the load differently than a conventional I-beam in 1989. When this happens, you have catastrophic engine failure. The reason an H-beam is stronger is between the slots in the side of the rod, you have a column of steel that runs from the big end of the rod up to the wrist pin where it wraps around the underside of the wrist pin. An H-beam also has a front and back plate, all of which is directly under the wrist pin so you actually have more mass below the wrist pin which is where it needs to be and it handles the load better.

2,126 posts

·

Joined 2007

Always good info' from that Molnar guy. I saw an interview with him at PRI last year? and you could tell he knew his shit through-n-through, because he "could explain it simply enough" (to borrow from ol' Albert).

1,993 posts

·

Joined 2009

I agree with the Molnar info above.

If fatigue resistance is the property being keyed in on, a rule of thumb (when comparing similar alloys) is that fatigue life is proportional to tensile strength. So yes, where 300m shines is way up there in UTS. Making a rod at 50 HRc is simply too expensive (everything would be ground) but it would work great. But for an axle shaft....potentially a far better opportunity for working out.

The application and a reasonable manufacturing window to meet those requirements have to be mated well to make a part viable.

If fatigue resistance is the property being keyed in on, a rule of thumb (when comparing similar alloys) is that fatigue life is proportional to tensile strength. So yes, where 300m shines is way up there in UTS. Making a rod at 50 HRc is simply too expensive (everything would be ground) but it would work great. But for an axle shaft....potentially a far better opportunity for working out.

The application and a reasonable manufacturing window to meet those requirements have to be mated well to make a part viable.

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

- posts

- 24M

- members

- 152K

- Since

- 2005

A forum community dedicated to drag racing drivers and enthusiasts. Come join the discussion about racing, builds, pro mods, hot rods, events, turbos, nitrous, superchargers, and more!

Top Contributors this Month

View All

VinnyVette9340

1.2K Replies

70FG

1.2K Replies

Steve.k

1K Replies