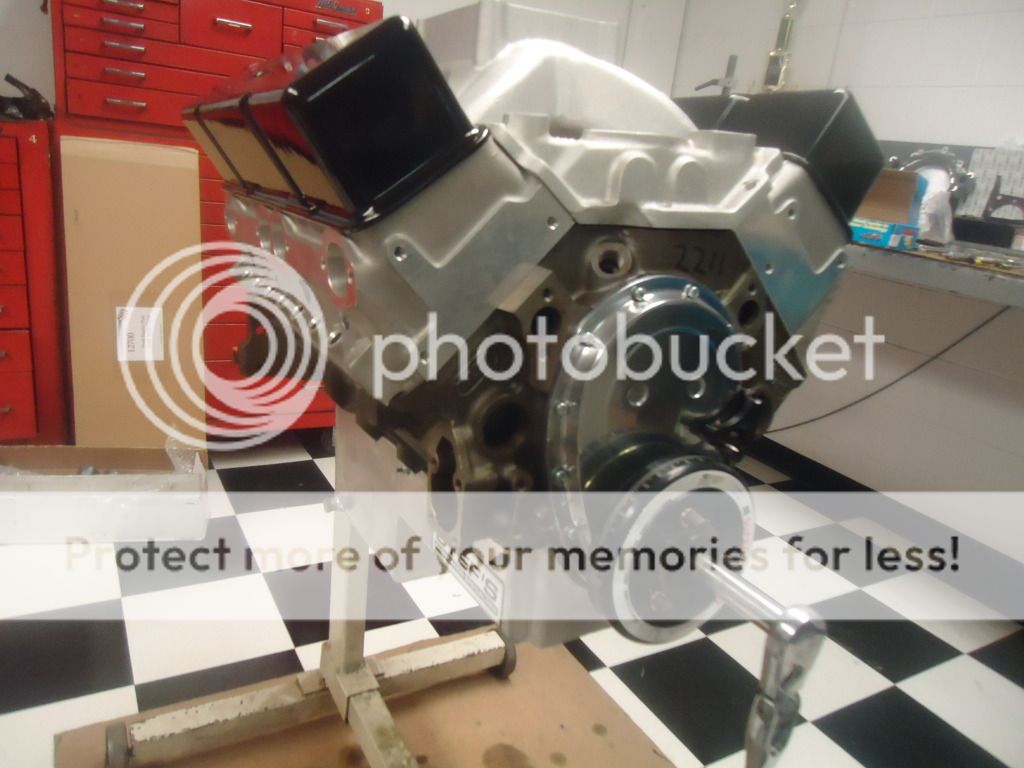

I would like to start by thanking Joe Irwin of Fast Forward Race Engines of Florida for helping me for the last two years on this build. Joe, his fiance Gina and Troy Pirez Jr. have helped me build the baddest bullet my money could buy. This project as many of you know was put together one piece at a time as my pay check would allow. A short run down of the motor includes the following:

Dart Little M with steel cap upgrade (not the sportsman version)

Callies Dragon slayer crank and H beam rods

Diamond custom pistons

Bullet cam/ crower lifters/ trend pushrods

CFE BMF 248cc 18 degree heads

Jesel rockers speced by Chris Uratchko

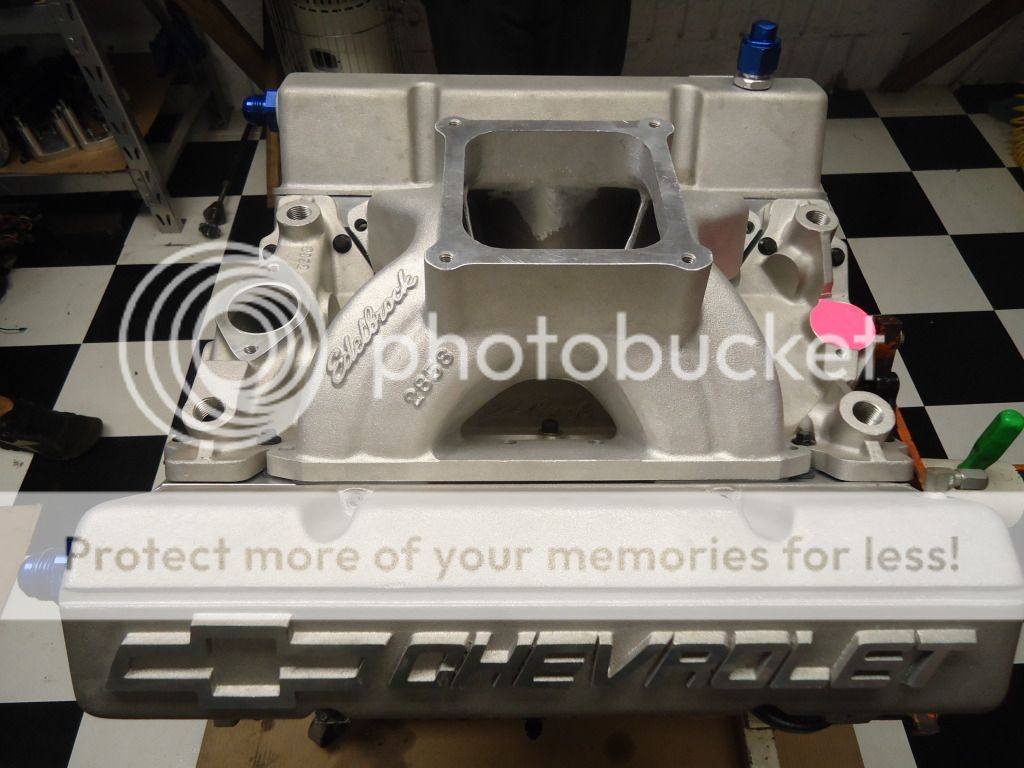

Edelbrock 2992 lower 2858 upper 4500 Intake pieces

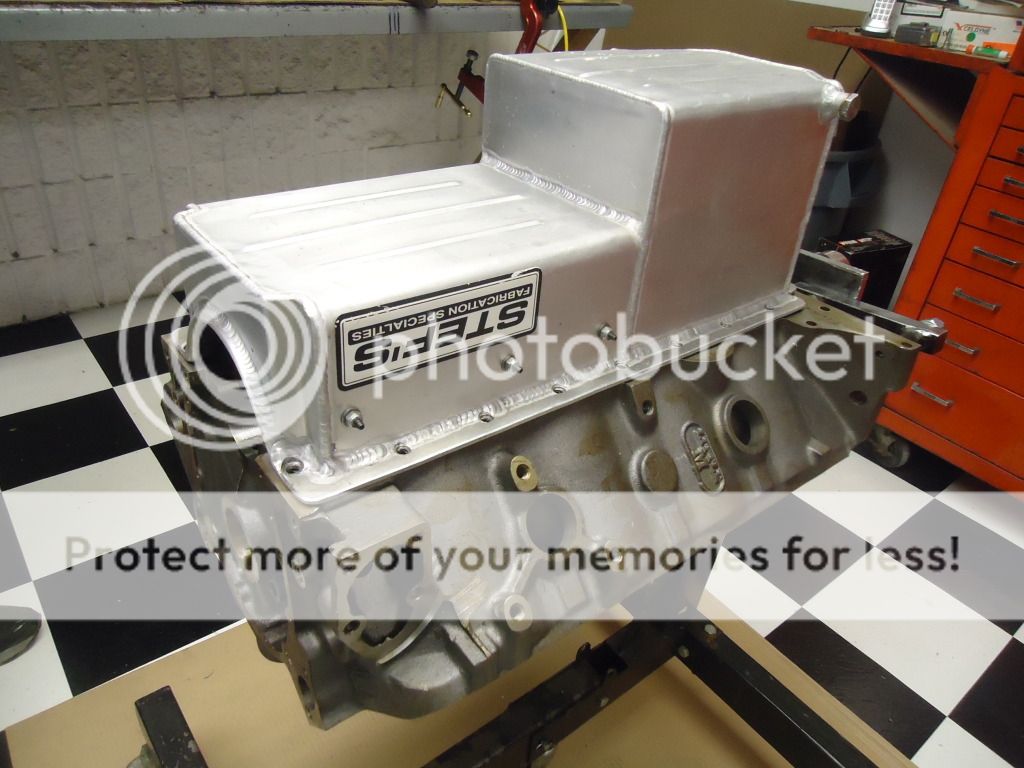

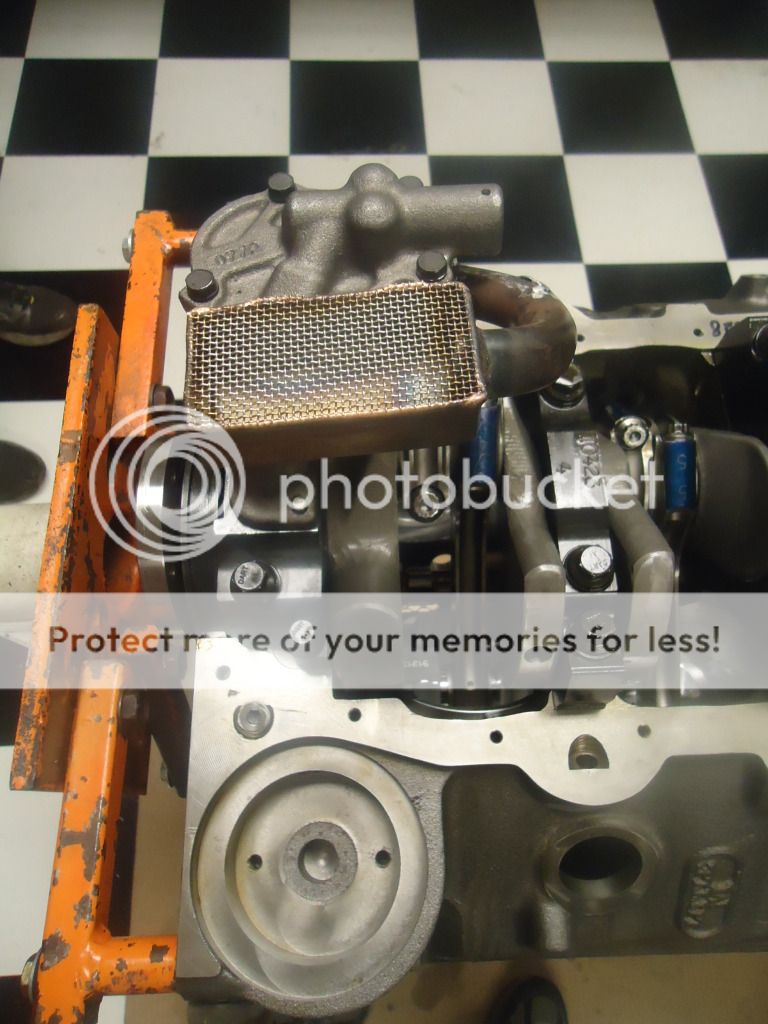

Stefs oil pan housing a Melling big block oil pump

ATI aluminum hub balancer and flexplate

ARP fastners and hardware throughout

Cometic MLS gaskets, Felpro for the rest

Rollmaster chain

Were looking for over 700 horse on this 11.7 to 1 compression pump gas piece. Motor is built for moderate nitrous too as the combination develops.

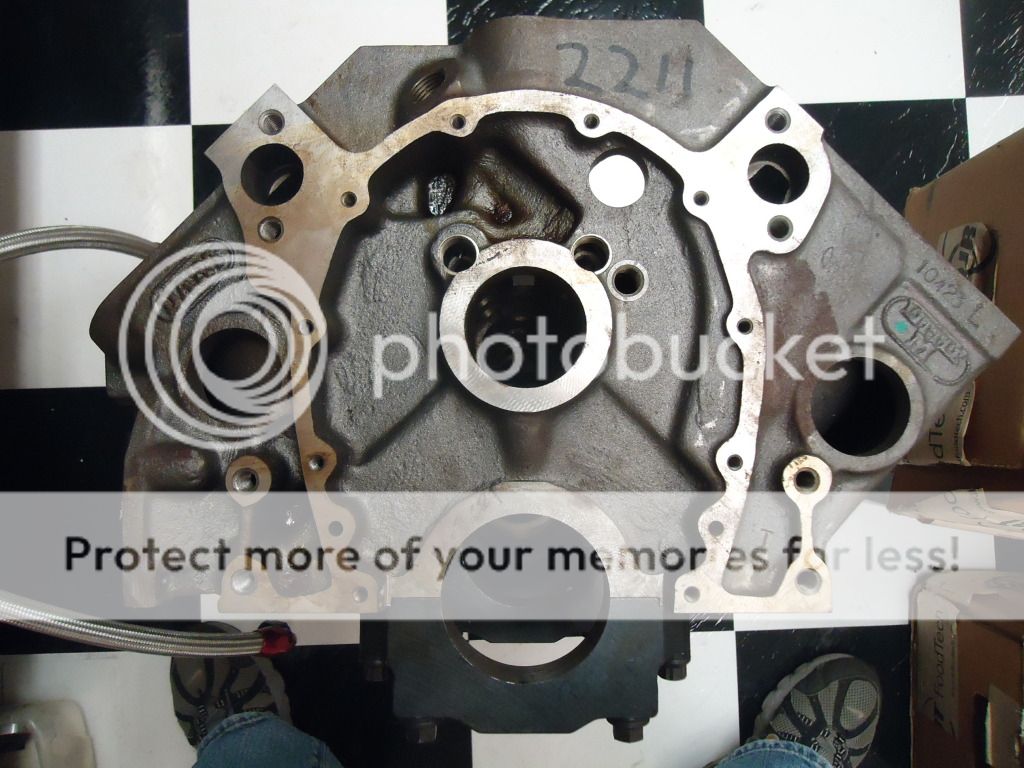

Started with this pile of parts

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

Resting in the living room waiting for a few more parts and them the installation in the Blazer for some new fast time slips.

![Image]()

I would like to again thank Joe at Fast Forward Race Engines for the great build experience and the attention to detail on this build. Now I need a few more parts to complete the motor and make it ready to drop in. If you guys have any questions, I will answer them all!

Dart Little M with steel cap upgrade (not the sportsman version)

Callies Dragon slayer crank and H beam rods

Diamond custom pistons

Bullet cam/ crower lifters/ trend pushrods

CFE BMF 248cc 18 degree heads

Jesel rockers speced by Chris Uratchko

Edelbrock 2992 lower 2858 upper 4500 Intake pieces

Stefs oil pan housing a Melling big block oil pump

ATI aluminum hub balancer and flexplate

ARP fastners and hardware throughout

Cometic MLS gaskets, Felpro for the rest

Rollmaster chain

Were looking for over 700 horse on this 11.7 to 1 compression pump gas piece. Motor is built for moderate nitrous too as the combination develops.

Started with this pile of parts

Resting in the living room waiting for a few more parts and them the installation in the Blazer for some new fast time slips.

I would like to again thank Joe at Fast Forward Race Engines for the great build experience and the attention to detail on this build. Now I need a few more parts to complete the motor and make it ready to drop in. If you guys have any questions, I will answer them all!