Whats the easiest/best fix for a stripped rocker arm stud hole in an aluminum head? Thread that stripped was a 7/16-14, can I retap to 1/2-13 and get an oversized stud or just drill it out and put a helicoil in it? I want to remove as little material as possible since it's still in the car.

Rubberduck406

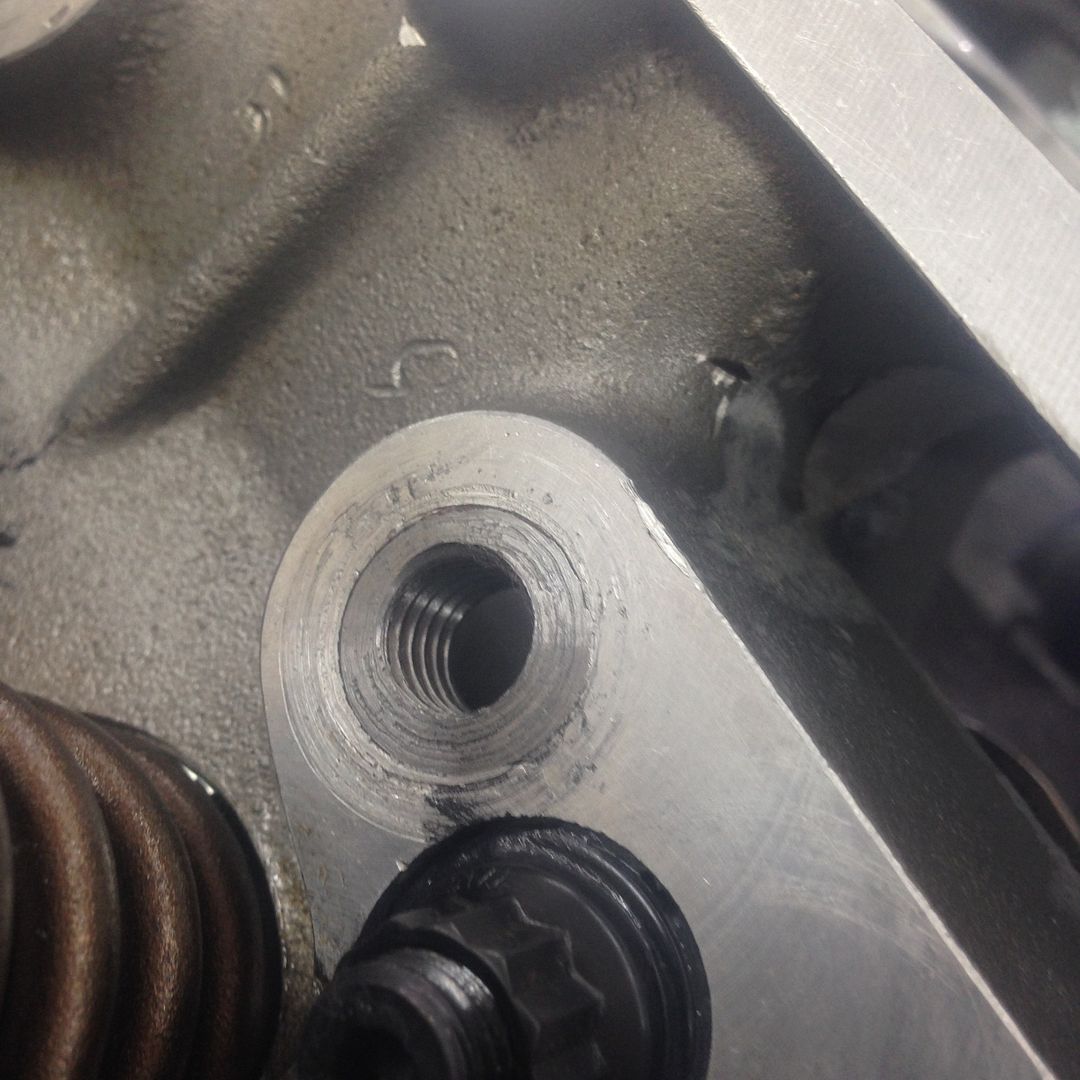

Stripped rocker stud hole

1 reading

Rubberduck406

Discussion starter

516 posts

·

Joined 2011

- Add to quote Only show this user

Whats the easiest/best fix for a stripped rocker arm stud hole in an aluminum head? Thread that stripped was a 7/16-14, can I retap to 1/2-13 and get an oversized stud or just drill it out and put a helicoil in it? I want to remove as little material as possible since it's still in the car.

1,943 posts

·

Joined 2008

Helicoil works best. I had to do the same thing before. It's actually stronger then your old aluminum threads you just stripped out.

286 posts

·

Joined 2007

Just curious, SB, BB, intake or exhuast??? Being in the car will make any repair more difficult. It will require some type of guide or bushing when drilling for fix.

Towards the end of last year we repaired/corrected 8 heads with the identical issue. We have an excellent procedure to make "better-than-new" fix. All were intake holes on the BB 23* platform.

You may be best served removing the head and "fixing" all the holes at the same time if they are the BB intakes? On the BB's excessive porting on the castings compound's the risk of failure!

Thanks, Gary in N.Y.

P.S. The actual fix uses a 3/8" pipe plug. You most likely won't be able to redo a conventional heli-coil due to the damage?

Towards the end of last year we repaired/corrected 8 heads with the identical issue. We have an excellent procedure to make "better-than-new" fix. All were intake holes on the BB 23* platform.

You may be best served removing the head and "fixing" all the holes at the same time if they are the BB intakes? On the BB's excessive porting on the castings compound's the risk of failure!

Thanks, Gary in N.Y.

P.S. The actual fix uses a 3/8" pipe plug. You most likely won't be able to redo a conventional heli-coil due to the damage?

106 posts

·

Joined 2013

I just went through this on my BBC as it had started to pull a few out and I had all of them replaced with time-serts. They are not cheap but have not had one problem since.

Rubberduck406

Discussion starter

516 posts

·

Joined 2011

It's the #2 intake stud on a sbc. The lower portion of it sticks down into the intake runner just a bit. I just ordered the Timesert kit and .400" long inserts. They seem to be a better mouse trap than helicoils.

13,484 posts

·

Joined 2009

the next one to pull / strip out is just around the corner...

what EXACT HEAD is this...??

THEY AINT ALL THE SAME...!!!

what EXACT HEAD is this...??

THEY AINT ALL THE SAME...!!!

Rubberduck406

Discussion starter

516 posts

·

Joined 2011

23* 200cc CNC ported Pro Topline. New Zealand casting I think.

836 posts

·

Joined 2013

I had just one do it on a sbf . Can't recall if I put a time cert or just a hardened heli coil . It didn't take much drilling since threads was gone. It cleaned right up . The new piece just cut right in there and like said was better than the old aluminum threads. Guy who set the rockers got a little carried away and they was older heads so they had plenty of rockers tightened down over the years. Never had a problem after that one hole or any others running low 10s for a long time ,and was still doing great when I sold it !

212 posts

·

Joined 2007

timesert, helicoil... they all work fine...

Some OEM aluminum heads come with helicoils in there

Some OEM aluminum heads come with helicoils in there

Rubberduck406

Discussion starter

516 posts

·

Joined 2011

Well I put the time sert in tonight and it started to pull it out as I was torquing the stud. I'm going to pull the head and try a Big Sert. If that doesn't get it I don't know what I'll do. Is it just a soft spot in the casting or something else?

6,475 posts

·

Joined 2010

You could have them welded up with some stronger alloy rod and re-machined/threaded. Be stronger than new

Rubberduck406

Discussion starter

516 posts

·

Joined 2011

23 posts

·

Joined 2010

This is what you need

http://www.mscdirect.com/browse/tn/...erts/Thread-Locking-Inserts?navid=12106001#navid=12106001+4294914258+4288246159

These work great and whats really nice is they come in a thick or thin insert, meaning if you really screwed up the hole you can use the thick one and still use the correct bolt.

I use these all the time on the ls engine manifold bolts at work, never had one fail yet but I have had all sorts of helicoil etc fail. These are what a local gm dealer uses to repair all sorts of parts especially on the old caddy northstars.

You can look around to find the install instructions or I can post them on monday when I get to work. Basically you need to chamfer the top of the hole a little so the tangs don't interfere with screwing it in. They have a tool to help pound the tangs in but its not necessary, you can just take a punch and pound them in taking care to not bend them.

I hope that helps, oh and I'm sure you can get them at fastenal or grainger too, I just know we get them from msc.

Good Luck

http://www.mscdirect.com/browse/tn/...erts/Thread-Locking-Inserts?navid=12106001#navid=12106001+4294914258+4288246159

These work great and whats really nice is they come in a thick or thin insert, meaning if you really screwed up the hole you can use the thick one and still use the correct bolt.

I use these all the time on the ls engine manifold bolts at work, never had one fail yet but I have had all sorts of helicoil etc fail. These are what a local gm dealer uses to repair all sorts of parts especially on the old caddy northstars.

You can look around to find the install instructions or I can post them on monday when I get to work. Basically you need to chamfer the top of the hole a little so the tangs don't interfere with screwing it in. They have a tool to help pound the tangs in but its not necessary, you can just take a punch and pound them in taking care to not bend them.

I hope that helps, oh and I'm sure you can get them at fastenal or grainger too, I just know we get them from msc.

Good Luck

286 posts

·

Joined 2007

Your best bet is really with a 3/8" NPT pipe plug. Like I mentioned earlier I've done numerous repairs over the years using this method. This repair needs a "clean" .578" hole to be effective with the 3/8" tap. With the head on the bench it's an easy fix.

We've been talking back and forth with AFR just recently about this issue.

Years ago we were impressed with the very first set of the older Pro-Topline ((BBC) castings we removed from the boxes and saw 1 piece inserts in ALL the intake rocker stud holes. We thought this was one of the best selling points about these "new" castings. We based all our future repairs on this method, going right to the pipe plug setup.

I've done a few sets of brand new BB's before they were even used just to prevent this very issue.

The first photo below shows the tooling, the second shows an Edelbrock head getting the repair!

Thanks, Gary in N.Y.

P.S. Your issue is not as prevalent on the SB platform as it is on the BB's, but this repair method is the way to go. We use an "interupted" thread 3/8" NPT pipe tap, very little effort cutting the threads in aluminum. Also the pipe tap gets Loctited in place and cannot work itself loose! I have seen these repairs required even on shaft-mount rockers, if the ride sees much use it MAY eventually become an issue. Can save much grief down the road??

We've been talking back and forth with AFR just recently about this issue.

Years ago we were impressed with the very first set of the older Pro-Topline ((BBC) castings we removed from the boxes and saw 1 piece inserts in ALL the intake rocker stud holes. We thought this was one of the best selling points about these "new" castings. We based all our future repairs on this method, going right to the pipe plug setup.

I've done a few sets of brand new BB's before they were even used just to prevent this very issue.

The first photo below shows the tooling, the second shows an Edelbrock head getting the repair!

Thanks, Gary in N.Y.

P.S. Your issue is not as prevalent on the SB platform as it is on the BB's, but this repair method is the way to go. We use an "interupted" thread 3/8" NPT pipe tap, very little effort cutting the threads in aluminum. Also the pipe tap gets Loctited in place and cannot work itself loose! I have seen these repairs required even on shaft-mount rockers, if the ride sees much use it MAY eventually become an issue. Can save much grief down the road??

13,484 posts

·

Joined 2009

pipe thread was / is a secret that I was not going to talk about.

still aint the type of repair to do without it being up in a rigid fixture to make certain it is square!!!!

seen a few totally fucked up by some garage idiot that then drilled and tapped in crooked..

and when the girdle was installed it bent the stud..

again,..... this is a job for a brigeport or stiff fixture in a seat and guide machine

still aint the type of repair to do without it being up in a rigid fixture to make certain it is square!!!!

seen a few totally fucked up by some garage idiot that then drilled and tapped in crooked..

and when the girdle was installed it bent the stud..

again,..... this is a job for a brigeport or stiff fixture in a seat and guide machine

13,484 posts

·

Joined 2009

weld the butt end of plug from inside the port to make it stronger..

...........next time do not buy heads that are thin in this area....

...........next time do not buy heads that are thin in this area....

Rubberduck406

Discussion starter

516 posts

·

Joined 2011

Thread it in and weld the bottom? I'm going to take it to my engine guy Monday and see what he says.

And the last part will be remembered from now on. The simple upgrade to 7/16 studs and girdles has turned into a freakin nightmare.

And the last part will be remembered from now on. The simple upgrade to 7/16 studs and girdles has turned into a freakin nightmare.

13,484 posts

·

Joined 2009

we do this sort of thing all the time...

it is much stronger...since the plug is a solid billet or forged material...not the cast material...

it is much stronger...since the plug is a solid billet or forged material...not the cast material...

1,044 posts

·

Joined 2009

Is the plug you use steel or aluminum ? I ask because someone said to thread the plug in and weld from the bottom, as in alum head and plug. But this seems that it would only be slightly stronger. Was also mentioned to locktite the plugs, as in a steel plug in an aluminum head, witch to me would be a much better repair. Also, I have a bare set of Brodix BB2 Plus heads, should this repair be made before I even run them ?

2,934 posts

·

Joined 2011

Heli-coil or similar product will work well for this type of repair. I would recommend, as ordinary builder stated in a previous post, that the head be removed and the drilling/machining operations be done on a Bridgeport mill or a seat and guide machine. Drilling and tapping while the head is on the vehicle will result in a stud that is not installed straight in about 99.9% of the time. If the finished stud is off by just a few degrees, it will cause problems with rocker arm function. Needs to be done right, or not at all.

7,390 posts

·

Joined 2013

I did a helicoil emergency repair using the stud girdle as a guide and a bushing around the tap. So far, so good.

6,475 posts

·

Joined 2010

Now I can see this happening in a pinch .....  . Don't like the free hand idea, wouldn't trust it

. Don't like the free hand idea, wouldn't trust it

Rubberduck406

Discussion starter

516 posts

·

Joined 2011

I dropped the head off on my lunch break. Should have it back by Friday so I'll post some pics of the repair job.

Rubberduck406

Discussion starter

516 posts

·

Joined 2011

1,200 posts

·

Joined 2007

Certainly wouldn't hurt anything D-dog, especially with an aggressive cam and high spring pressures. I'd think it would be some good insurance.

1,044 posts

·

Joined 2009

Yeah, I thought about it and I'm gonna do it to help maybe eliminate problems after this thing's running . I'm probably gonna build a fixture for my Bridgeport this weekend.

6,164 posts

·

Joined 2009

We use all thread to repair them. did it at the race track head on the engine once

Rubberduck406

Discussion starter

516 posts

·

Joined 2011

I don't remember if the plug he used was steel or aluminum. I think it was aluminum, but it wasn't a cast piece so it was stronger than the aluminum in the head. It's been in there for a year and hasn't given any trouble (knock on wood).

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

- posts

- 24M

- members

- 152K

- Since

- 2005

A forum community dedicated to drag racing drivers and enthusiasts. Come join the discussion about racing, builds, pro mods, hot rods, events, turbos, nitrous, superchargers, and more!

Top Contributors this Month

View All

VinnyVette9340

1.3K Replies

70FG

1.2K Replies

Steve.k

1K Replies